Table of Contents

Introduction

For businesses operating in the food industry, the packaging of products is crucial. A well-packaged product can help improve its shelf-life, transportation, and overall quality. The automatic granule food bagging machine is an essential piece of equipment that can help make the packaging process seamless and efficient.

What is an Automatic Granule Food Bagging Machine?

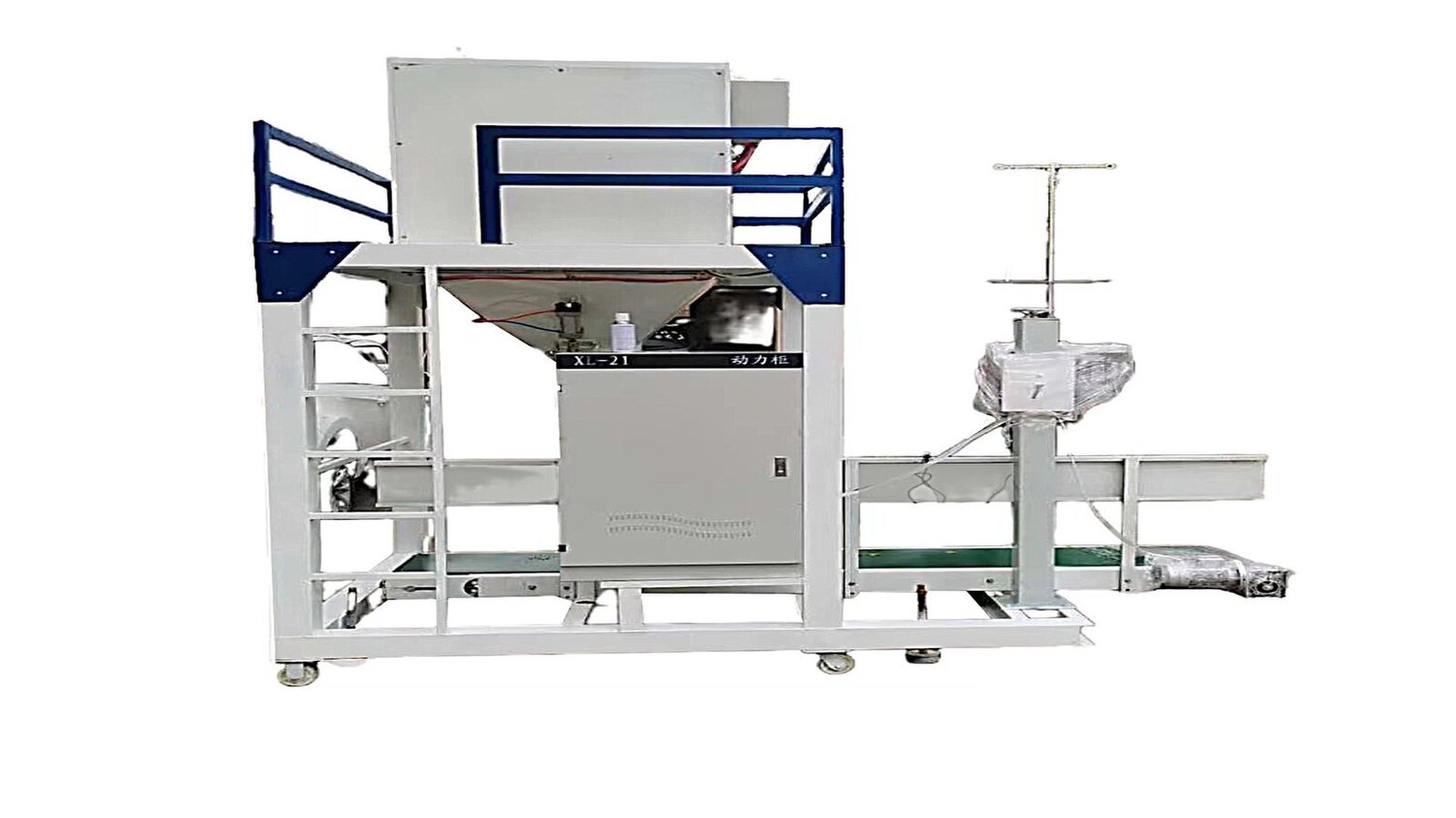

An automatic granule food bagging machine is a device used to package granular food products. The machine is designed to automate the bagging process, with minimal human intervention required. The machine can handle different types of packaging materials, including plastic, paper, and nylon bags, among others.

How Does the Automatic Granule Food Bagging Machine Work?

The automatic granule food bagging machine operates by taking in food granules from a hopper, which then dispenses the granules into the bags. The machine seals the bags and cuts them to the desired size. The packed bags are then transferred to a conveyor for further processing.

Advantages of Using an Automatic Granule Food Bagging Machine

There are several advantages of using an automatic granule food bagging machine, including:

- Improved efficiency and productivity due to automation

- Reduced labor costs as minimal human intervention is required

- Reduced chances of contamination due to minimal human contact with the product

- Precision and accuracy in the bagging process, resulting in uniform bags with the right weight and size

- Customizable settings, allowing for the bagging of different products in different bag sizes

Types of Automatic Granule Food Bagging Machines

There are different types of automatic granule food bagging machines, depending on the packaging material and bag size. The most common types include:

- VFFS (Vertical Form Fill Seal) machines, which form bags from a roll of film

- HFFS (Horizontal Form Fill Seal) machines, which use pre-made bags that are fed into the machine

- Premade Pouch Filling Machines, which operate by filling pre-made pouches with food products

- Open Mouth Bagging Machines, which use pre-made open-mouth bags

Factors to Consider When Choosing an Automatic Granule Food Bagging Machine

Choosing the right automatic granule food bagging machine is crucial for the success of your food packaging business. Some of the key factors to consider when selecting a machine include:

- Type of packaging material and bag size

- Production speed and capacity of the machine

- Level of automation and customization options

- Reliability and ease of maintenance

- Safety features, such as automatic shut-off and emergency stop buttons

Cost of an Automatic Granule Food Bagging Machine

The cost of an automatic granule food bagging machine depends on several factors, including the type of machine, production capacity, and level of automation. On average, the cost of an entry-level machine is around $10,000, while high-end machines can cost over $100,000.

Maintenance and Upkeep of an Automatic Granule Food Bagging Machine

Maintaining an automatic granule food bagging machine is crucial to ensure its longevity and optimal performance. Some of the maintenance tasks include regular cleaning, lubrication, and replacing worn-out components. It is essential to follow the manufacturer's instructions and schedule regular service checks from authorized technicians.

Conclusion

The automatic granule food bagging machine is a vital tool for businesses involved in the food packaging industry. Choosing the right machine for your business is crucial, and you should consider factors such as production capacity, type of packaging material, and level of automation. Proper maintenance is also essential to ensure the machine's optimal performance and longevity.