The single-screw press is a specialized mechanical device widely used in industrial processes for compressing materials. Its primary function revolves around utilizing a single rotating screw to generate pressure, which compacts raw materials or extracts valuable substances. Unlike multi-screw systems, the single-screw press offers simplicity, reliability, and efficiency, making it a favored choice in various industries including oil extraction, waste management, and material recycling.

Core Components and Mechanical Design

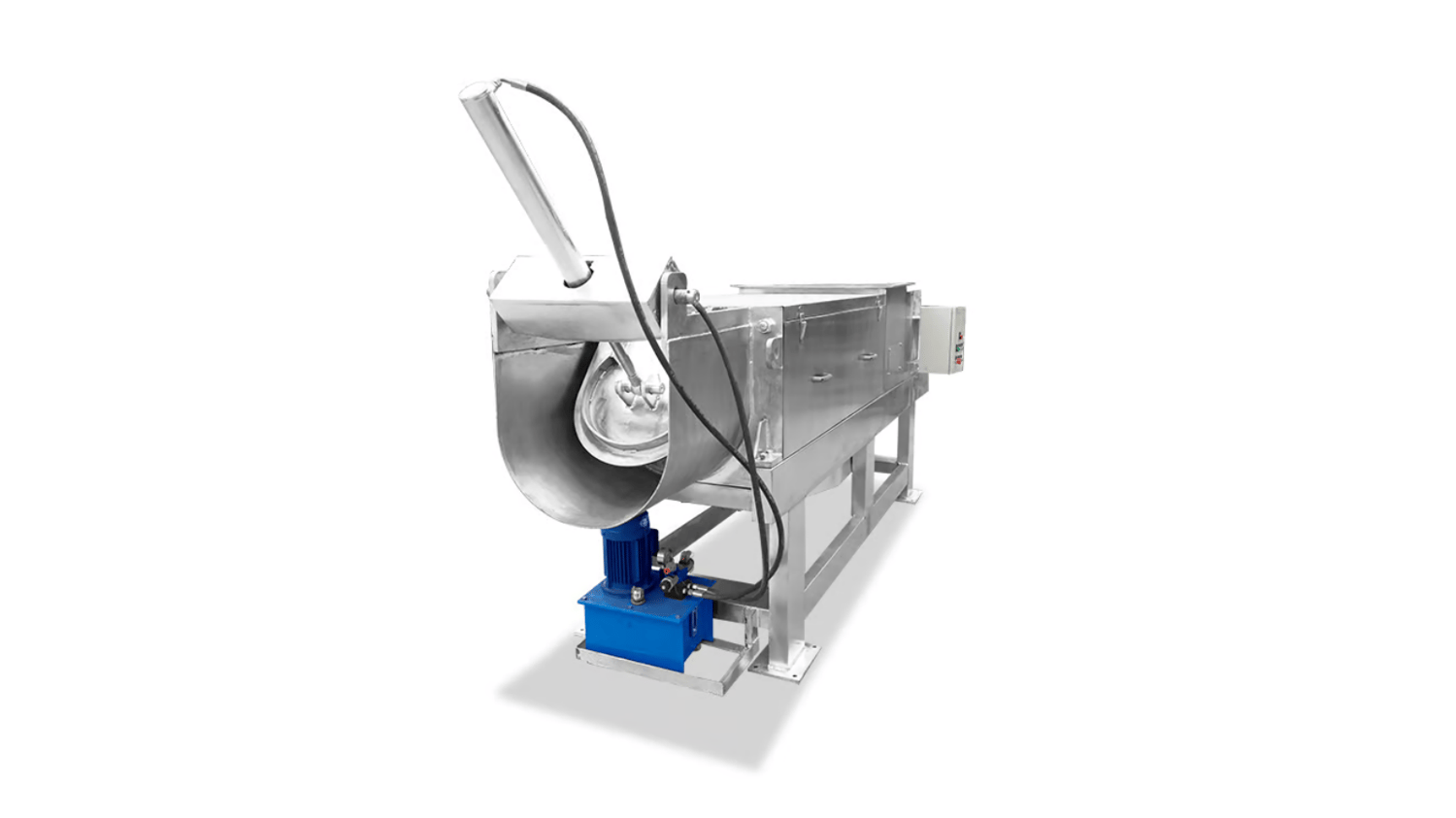

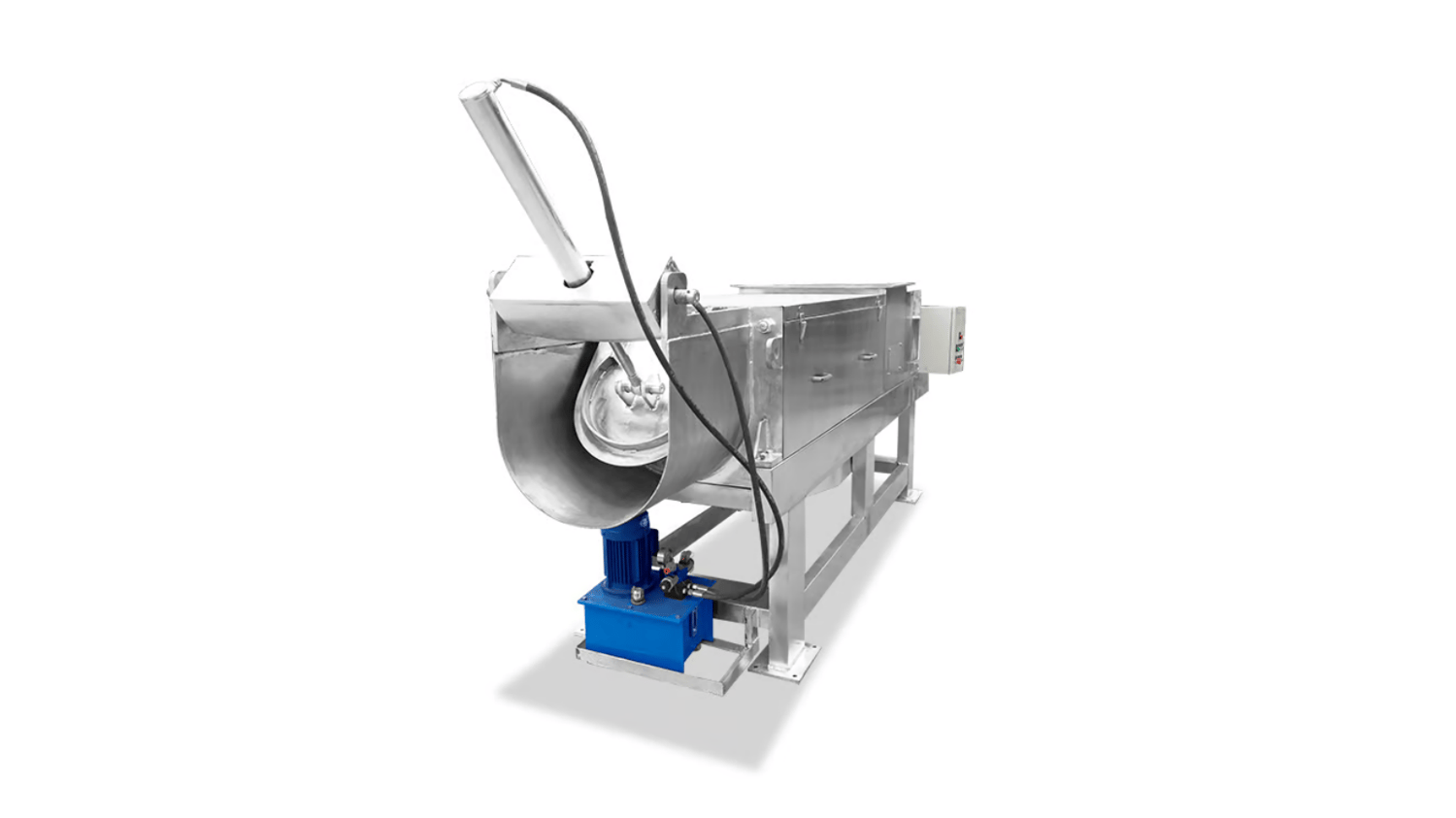

Central to the single-screw press is its helical screw, which operates inside a barrel to convey and compress material. The design includes a feed hopper, the screw, a cage or screen for filtration, and a drive mechanism. The screw’s pitch and diameter control the rate of compression, while the barrel often features perforations to allow liquid or fines to be separated from solids. This mechanical design enables continuous processing with minimal downtime, boosting productivity.

Operating Principles and Process Flow

Operating on the principle of volumetric displacement, the single-screw press continuously moves material from the feed inlet through the screw channel. As the material progresses, the decreasing screw pitch creates increasing pressure, forcing liquid or oil to separate through the barrel’s perforations. The compressed solids, or cake, exit the press at the discharge end. This process allows for efficient dewatering or oil extraction without the need for extensive pre-treatment.

Material Compatibility and Versatility

Single-screw presses demonstrate remarkable versatility by processing a broad range of materials. From oilseeds like sunflower and rapeseed to biomass, sludge, and even plastics, these presses adjust to various feedstock consistencies and moisture contents. This adaptability allows industries to optimize resource recovery through scale-up or modification of press parameters, enhancing operational flexibility.

Applications in Oil Extraction Industry

Arguably the most prominent application of the single-screw press is in oil extraction. It serves as a prime tool for cold and hot pressing oilseeds, producing high-quality crude oil with minimal chemical use. The press’s ability to operate continuously while preserving oil characteristics makes it indispensable for edible oil producers. Moreover, it reduces solvent extraction dependency, aligning with environmental and health standards.

Advantages over Multi-Screw and Hydraulic Presses

Single-screw presses offer several advantages compared to other press types. They require less maintenance owing to simpler mechanical parts, operate with lower energy consumption, and maintain continuous processing without frequent stops. Additionally, they provide efficient moisture separation and handle variable feedstock without significant setup changes, giving them an edge over hydraulic or twin-screw alternatives.

Environmental Impact and Sustainability Benefits

Integrating a single-screw press into production lines promotes sustainability by enabling waste reduction and resource recovery. For example, it can dewater sludge, reducing landfill volumes, or recover oil from seeds, decreasing reliance on chemical solvents. The press’s energy efficiency further contributes to lower carbon footprints, supporting companies’ commitments to greener manufacturing practices.

Maintenance and Operational Considerations

Routine upkeep of single-screw presses involves inspection of screws for wear, cleaning screen cages to prevent clogging, and lubrication of drive components. Operators must monitor feed rates and moisture content to avoid overloading, which can reduce equipment lifespan. Proper maintenance ensures long-term reliability and consistent output quality, critical for industrial-scale production.

Technological Innovations and Automation Integration

Recent advancements in single-screw press technology include automation systems for real-time monitoring of pressure, temperature, and throughput. Integration with control systems allows for adaptive operation, optimizing performance based on feedstock variations. Additionally, materials engineering improvements have enhanced screw durability and corrosion resistance, increasing overall equipment lifespan.

Future Trends and Industry Outlook

The future of single-screw press technology is promising, with increasing demand in biofuel production, food processing, and waste management sectors. Advances focused on energy savings, modular designs, and enhanced control systems are expected to drive widespread adoption. As industries seek sustainable, efficient processing solutions, the single-screw press will continue to play a vital role in resource recovery and material processing.

Quote Inquiry

contact us