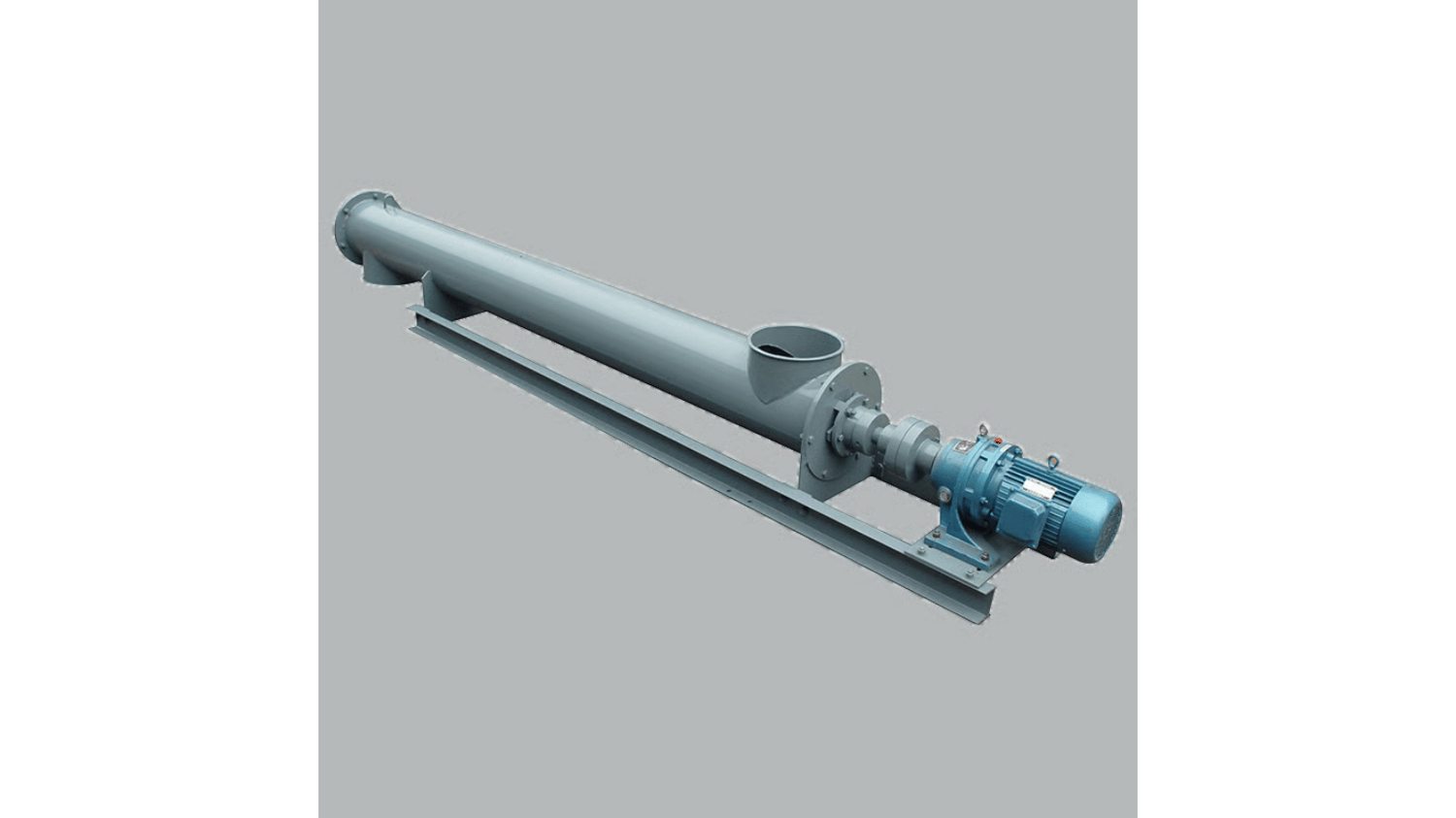

What is a Screw conveyor and How Does It Work?

A screw conveyor is a mechanical device used for moving bulk materials in various industries. It consists of a helical screw blade, also known as an auger, that rotates inside a tube or trough to push materials forward. This simple design efficiently transports powders, granules, and semi-solid materials horizontally, vertically, or at an incline. The consistent motion of the screw ensures materials are moved steadily, preventing blockages and enabling precise flow control.

Key Components and Construction of Screw Conveyors

Screw conveyors typically include the screw blade, trough or tube, shaft, bearings, and drive mechanism. The screw blades are commonly made from steel or stainless steel, designed for durability based on material characteristics. The trough can be U-shaped or tubular, open or enclosed, depending on the application environment. The drive system usually consists of an electric motor connected via gears or direct coupling, enabling adjustable speeds to suit different material flow rates.

Types of Screw Conveyors: Exploring Design Variations

Several types of screw conveyors exist, tailored for specific purposes. Standard screw conveyors move materials horizontally or slightly inclined. Vertical screw conveyors lift materials upward within a confined space. Tubular screw conveyors enclose the screw in a tube to prevent contamination or dust. Shaftless screw conveyors lack a central shaft and are ideal for sticky or stringy materials. Consideration of these types is essential when selecting the right conveyor for particular industries.

Material Handling Capabilities of Screw Conveyors

Screw conveyors can efficiently handle a broad range of materials, from dry powders like cement and flour to wet, sticky substances such as sludge and food waste. Their ability to convey materials with varying moisture content and particle size makes them versatile across industries. The choice of screw design—diameter, pitch, and screw pitch length—affects the conveyor’s efficiency and suitability for the transported material.

Applications Across Diverse Industries

Screw conveyors are widely used in agriculture, mining, manufacturing, food processing, and wastewater treatment. In agriculture, they transport grains and seeds. The mining sector uses them for moving minerals and ores. Food processing plants rely on screw conveyors for handling flour, sugar, and other ingredients hygienically. Additionally, wastewater treatment facilities use them to convey sludge and grit, demonstrating their critical role in efficient bulk-material management.

Advantages of Using Screw Conveyors in Material Transport

Screw conveyors offer several benefits, including compact design, reliability, and ease of operation. Their enclosed structure minimizes material losses and reduces contamination, making them suitable for sensitive materials. They also allow controlled and continuous material feed, which is essential for manufacturing and processing lines. Furthermore, screw conveyors can be installed in various layouts, saving space and adapting to complex plant configurations.

Limitations and Challenges in Screw Conveyor Usage

Despite their advantages, screw conveyors have limitations. They are generally not suitable for fragile materials that may degrade under mechanical stress. Additionally, screw conveyors can face wear and tear when handling abrasive materials, leading to maintenance challenges. Their efficiency decreases when conveying materials vertically over long distances. Addressing these challenges requires careful design choices and regular maintenance protocols.

Customization and Design Considerations

Customizing screw conveyors involves selecting appropriate materials, screw geometry, trough type, and drive mechanisms to suit specific applications. Factors such as material abrasiveness, moisture content, temperature, and flow characteristics influence design decisions. Advanced features like variable pitch screws or stepped flights can optimize the handling of particular materials. Proper customization increases conveyor lifespan and performance, enhancing overall operational efficiency.

Maintenance Practices to Ensure Longevity

Regular maintenance of screw conveyors is vital to prevent downtime and costly repairs. Lubricating bearings, inspecting screw flights for wear, and checking motor performance are common practices. Ensuring that conveyed material is consistent and free from foreign objects reduces the risk of blockages and damage. Proper alignment and tension adjustments in the conveyor’s drive system also contribute to reliable, long-term operation.

Future Trends and Technological Advancements

Emerging technologies are enhancing screw conveyor designs to improve energy efficiency and automation. Integration with control systems allows real-time monitoring of material flow and equipment condition. Improved materials and coatings increase resistance to abrasion and corrosion. Additionally, developments in screw conveyor design include modular components for easier installation and maintenance. These trends promise more sustainable and cost-effective bulk material handling solutions.

Quote Inquiry

contact us