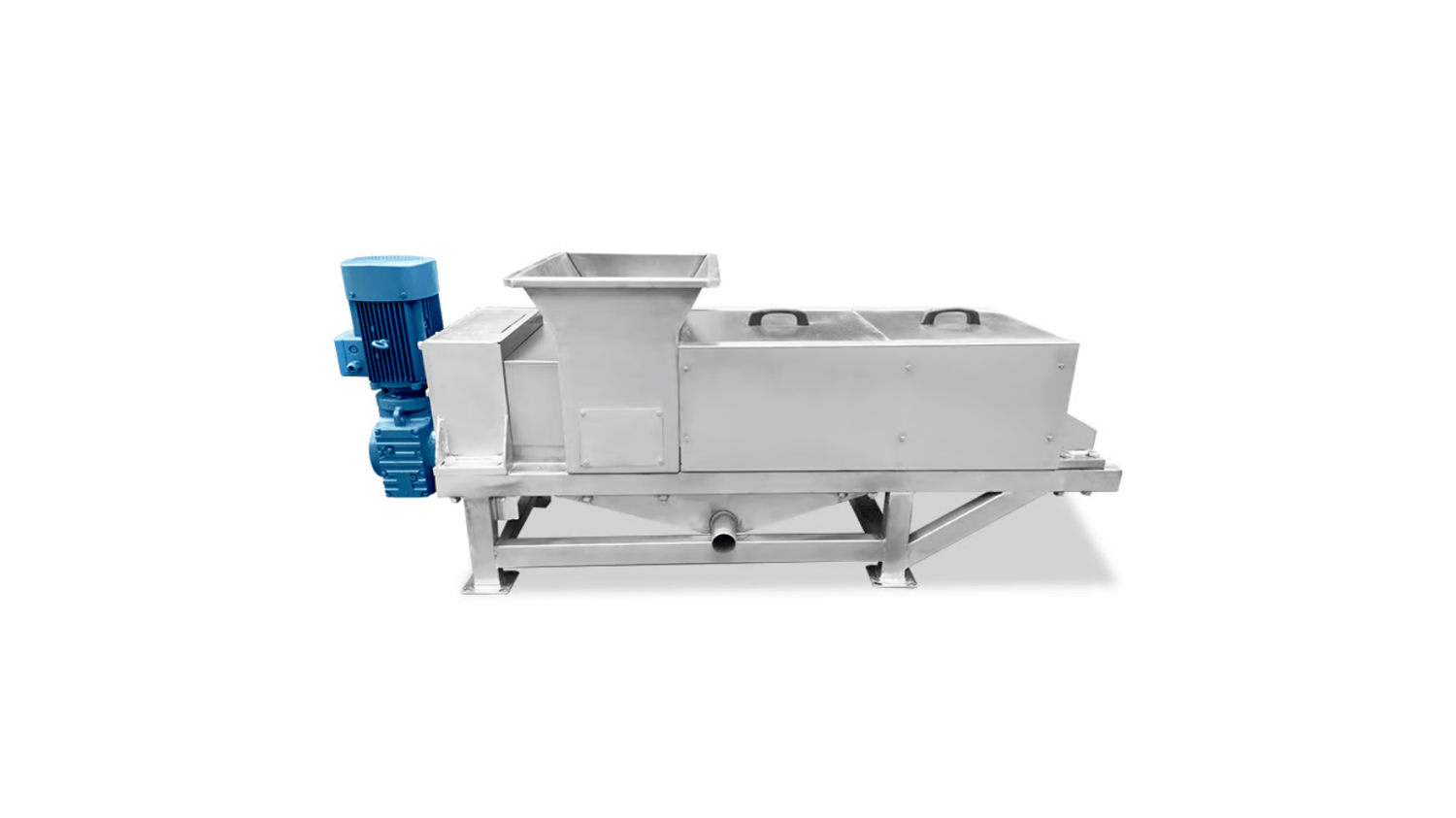

The double-screw press is a specialized mechanical device designed for continuous pressure application, predominantly in industrial extraction and dewatering processes. Unlike single-screw presses, this system employs two parallel screws that rotate synchronously, offering superior efficiency in material compression. By facilitating uniform pressure distribution across the material bed, double-screw presses enhance throughput and product quality, making them invaluable in sectors such as oil extraction, biomass processing, and chemical manufacturing.

Principles of Operation in Double-Screw Presses

At the core of the double-screw press is a pair of intermeshing screws housed within a press chamber. As the screws rotate, they draw raw material into the system, compressing it along the length of the press. This mechanical action expels liquids, such as oil or water, through perforations in the chamber walls, while solids are conveyed forward for discharge. The dual-screw setup provides balanced forces and prevents clogging, ensuring stable pressure application and consistent output throughout operation.

Advantages Over Single-Screw Press Systems

Double-screw presses offer several key benefits compared to their single-screw counterparts. Primarily, they enable higher throughput due to dual feeding and compressing mechanisms. The design also reduces material slip and recirculation, improving efficiency. Additionally, double-screw presses can handle a wider range of material viscosities and moisture contents, allowing for more versatile processing capabilities. Energy consumption tends to be lower per unit of processed material because of improved mechanical leverage and reduced friction.

Applications in Oilseed Processing

One of the most common uses of double-screw presses is in the oilseed industry for extracting vegetable oils. Seeds such as soybean, sunflower, and rapeseed are subjected to high-pressure compression, which separates the oil from the seed cake. The double-screw press’s continuous operation and efficient expulsion of liquid optimize oil recovery rates. Furthermore, the press’s mechanical reliability minimizes downtime, contributing to increased profitability in oil milling plants.

Role in Biomass Dewatering and Waste Management

Double-screw presses play a critical role in dewatering biomass materials, including agricultural residues, food waste, and sludge. By reducing moisture content, these presses facilitate easier handling, transportation, and subsequent processing of biomass. Their ability to process fibrous and heterogeneous waste streams with minimal clogging is particularly advantageous in waste management and biofuel production, where consistent feedstock quality is vital.

Customization and Design Variations

Manufacturers offer double-screw presses in various configurations to meet specific industrial requirements. Parameters such as screw diameter, pitch, length, and rotational speed can be tailored to accommodate diverse materials and desired throughput. Some models incorporate adjustable pressure zones or heating elements to improve processing efficiency. This customization allows operators to optimize the press performance for applications ranging from raw material pretreatment to final product refinement.

Maintenance and Durability Considerations

The durability of double-screw presses depends on material selection and design quality. Components are typically made from wear-resistant alloys to withstand abrasive feedstocks and high operational stress. Routine maintenance includes inspection of screw flights, bearings, and seals to prevent premature failure. Proper lubrication and timely replacement of worn parts extend service life, ensuring continuous high performance. The relative simplicity of mechanical design facilitates straightforward troubleshooting and repair.

Energy Efficiency and Environmental Impact

Double-screw presses are recognized for their energy-efficient operation when compared to other separation technologies. The mechanical compression does not rely on excessive heat, resulting in lower energy consumption levels. Additionally, efficient separation reduces the volume of waste generated, contributing to environmental sustainability. In biomass and waste treatment applications, the enhancement of dry matter content decreases the carbon footprint associated with transport and disposal.

Integration in Automated Industrial Processes

Modern double-screw presses can be integrated into automated production lines, allowing for seamless material handling and continuous operation. Sensors and control systems monitor variables such as pressure, temperature, and throughput rate, facilitating real-time adjustments to optimize output quality. This automation reduces labor costs and minimizes human error, making double-screw presses an asset in large-scale industrial environments requiring precision and consistency.

Future Trends and Innovations

Emerging innovations in double-screw press technology include the use of advanced materials to enhance wear resistance and lightweight construction to reduce energy requirements. Integration with digital monitoring and predictive maintenance platforms further improves reliability. Researchers are also exploring hybrid systems combining double-screw presses with other separation methods to enhance extraction efficiency and broaden application scope. These trends signal ongoing growth in the importance of double-screw presses across multiple industrial sectors.

Quote Inquiry

contact us