The double shaft crusher operation is a pivotal process in industries requiring efficient size reduction of various materials. Unlike single-shaft crushers, double shaft models use two parallel shafts equipped with interlocking rotors, enabling thorough crushing through a combination of cutting, shearing, and grinding. Understanding the operational principles behind this crusher type helps optimize performance and prolong equipment life.

Principle of Double Shaft Crusher Functionality

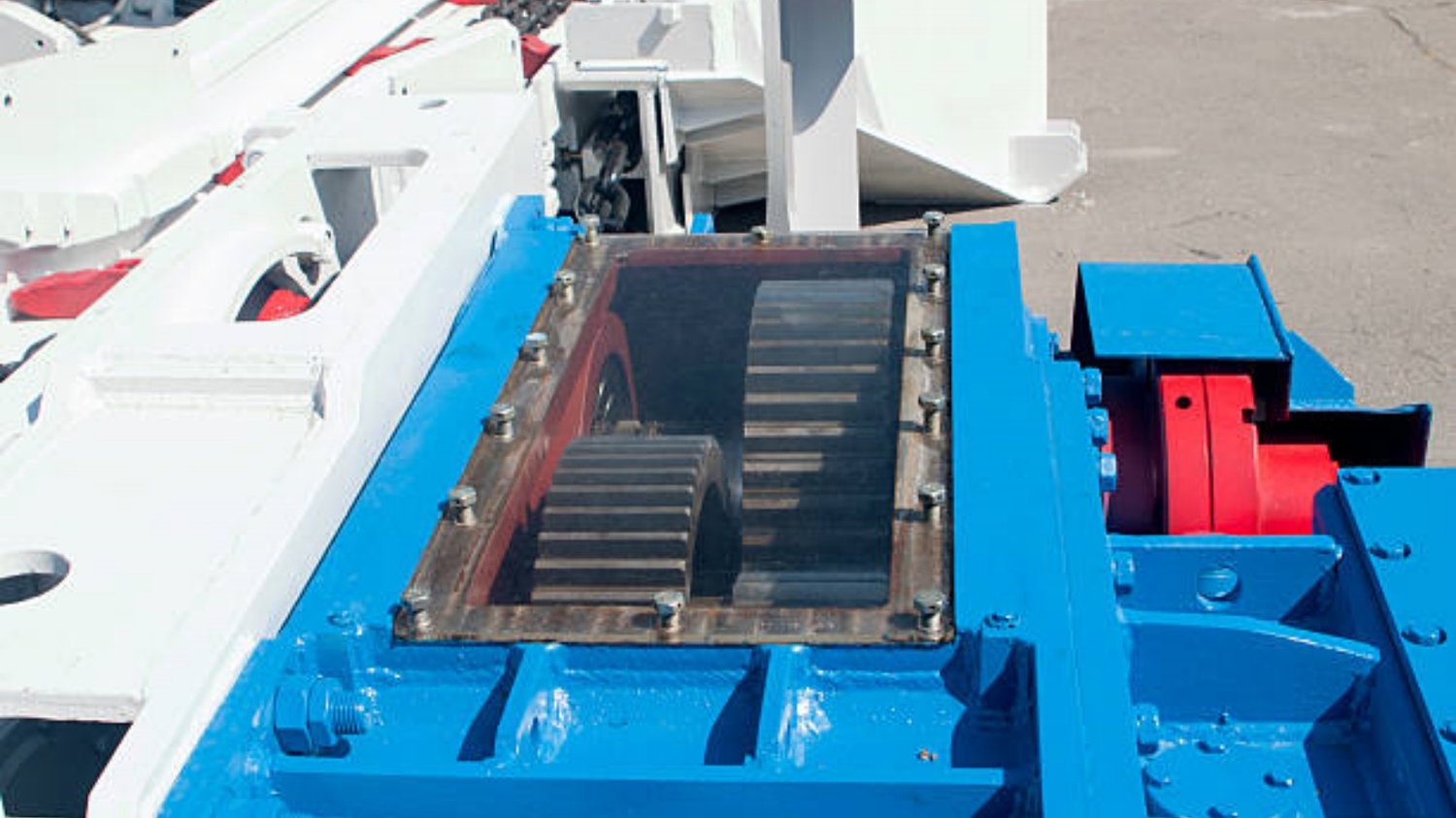

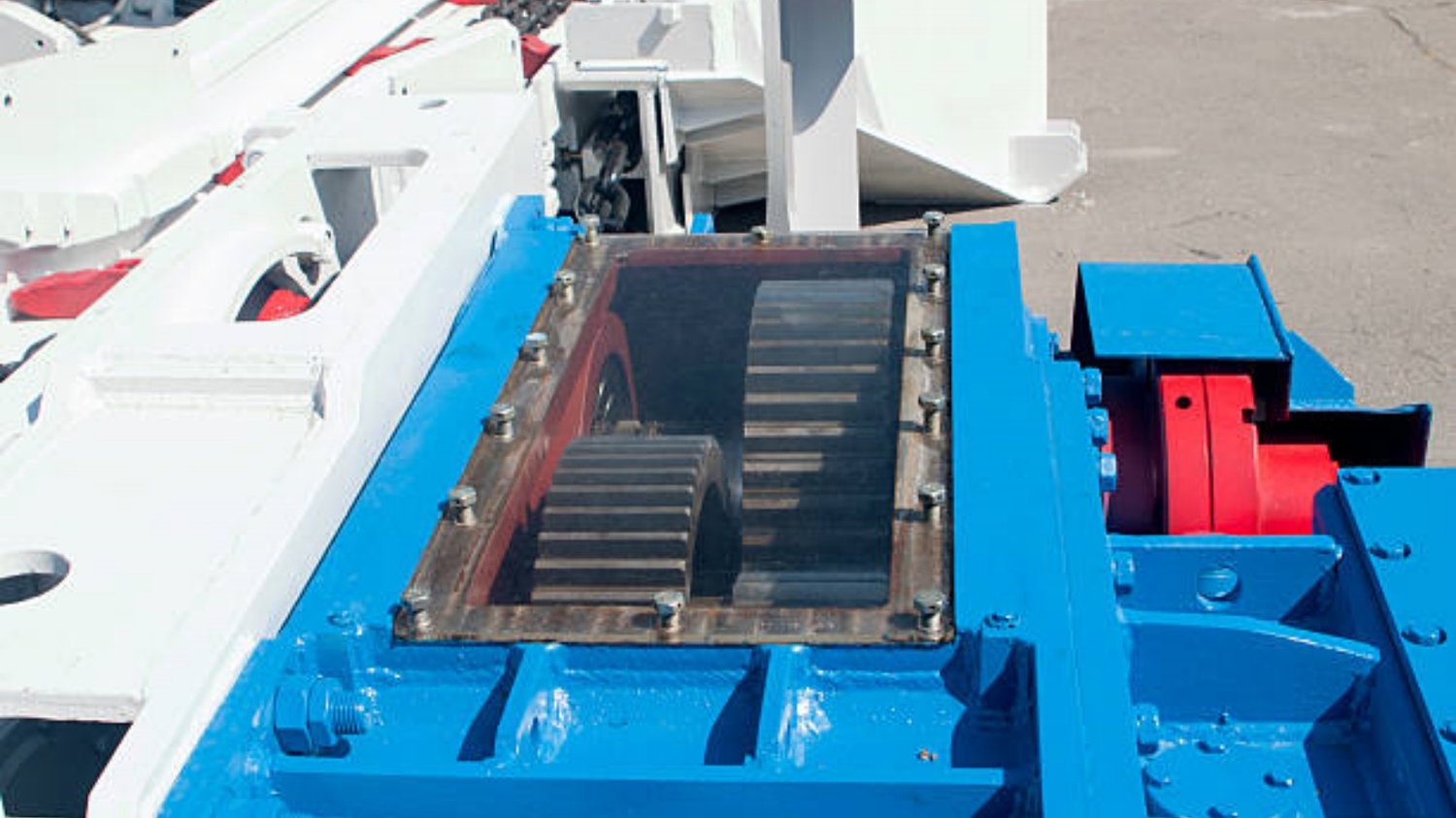

At the core of double shaft crusher operation lies the simultaneous movement of two shafts rotating in opposite directions. These shafts, fitted with robust hammers or knives, break down feed material by creating shear forces alongside impact. The intermeshing of blades ensures continuous crushing, making this design suitable for processing tough and fibrous materials effectively.

Material Compatibility and Application Scope

Double shaft crushers are versatile in handling a wide range of materials, including raw municipal waste, wood chips, plastics, and minor construction debris. Their operational design supports not only coarse crushing but also shredding applications, particularly important in recycling and waste management sectors where material uniformity and throughput are critical.

Advantages of Double Shaft Crusher Operation

One significant advantage of this crusher type is its ability to maintain consistent particle size output due to the uniform gap between the shafts. This results in high-quality output with minimal fines production. Furthermore, the operation is energy-efficient, reducing overall power consumption during crushing processes compared to other crusher types.

Safety Features Integrated in Double Shaft Crushers

Modern double shaft crusher operation incorporates safety mechanisms such as overload protection, automatic shutdown, and emergency stop systems. These features prevent equipment damage and protect operators from accidents, ensuring the crusher halts immediately upon detecting blockages or excessive load conditions.

Maintenance Practices for Optimized Double Shaft Crusher Operation

Regular maintenance is fundamental to sustaining efficient double shaft crusher operation. This involves periodic inspection of shredder blades, checking wear parts, lubrication of bearings, and monitoring shaft alignment. Prompt replacement of worn components prevents breakdowns, reducing downtime and increasing crusher reliability.

Control Systems Enhancing Double Shaft Crusher Performance

Advanced control systems integrated into double shaft crushers aid in real-time monitoring of operational parameters like torque, feed rate, and motor load. Automated feeders and adaptive speed controls help maintain optimal crushing conditions, improving throughput and reducing stress on mechanical components.

Energy Consumption and Environmental Impact

Double shaft crusher operation is designed to minimize energy consumption by optimizing rotor speed and feed volume. Lower power demand not only reduces operational costs but also contributes to environmental sustainability by decreasing carbon footprint associated with crushing processes.

Troubleshooting Common Issues in Double Shaft Crusher Operation

Common challenges faced during double shaft crusher operation include material jams, uneven wear of blades, and motor overloads. Identifying symptoms such as unusual vibrations or noise enables quick diagnosis. Implementing proper operational protocols and timely maintenance mitigates these problems, ensuring continuous productivity.

Future Trends and Innovations in Double Shaft Crusher Operation

Emerging technologies in double shaft crusher operation focus on integrating IoT sensors and AI-driven analytics for predictive maintenance and operational optimization. Such advancements promise increased machine uptime, enhanced safety, and further reductions in energy consumption, fostering smarter and more sustainable crushing operations.

Quote Inquiry

contact us