Material size reduction plays a crucial role in various industries, including manufacturing, pharmaceuticals, and recycling. By reducing the size of materials, companies can improve efficiency, lower production costs, and create products with better quality. This process involves breaking down large materials into smaller pieces, which can then be easily manipulated or processed further.

Methods of Material Size Reduction

There are several methods available for material size reduction, depending on the type of material and desired outcome. Some common techniques include crushing, grinding, shredding, and cutting. Each method has its advantages and limitations, so it's essential to choose the most suitable one based on the material properties and production requirements.

Crushing for Material Size Reduction

Crushing is a popular method for reducing the size of materials such as rocks, ores, and concrete. This process involves applying mechanical forces to break the material into smaller pieces. Crushers come in various types, including jaw crushers, cone crushers, and impact crushers, each designed for different applications and material sizes.

Grinding as an Effective Size Reduction Technique

Grinding is another common method used for material size reduction, especially for finer particles. This process involves using abrasive particles to remove material from a workpiece, resulting in a smaller particle size. Grinding is widely used in the food, chemical, and mining industries to create powders, pastes, and granules.

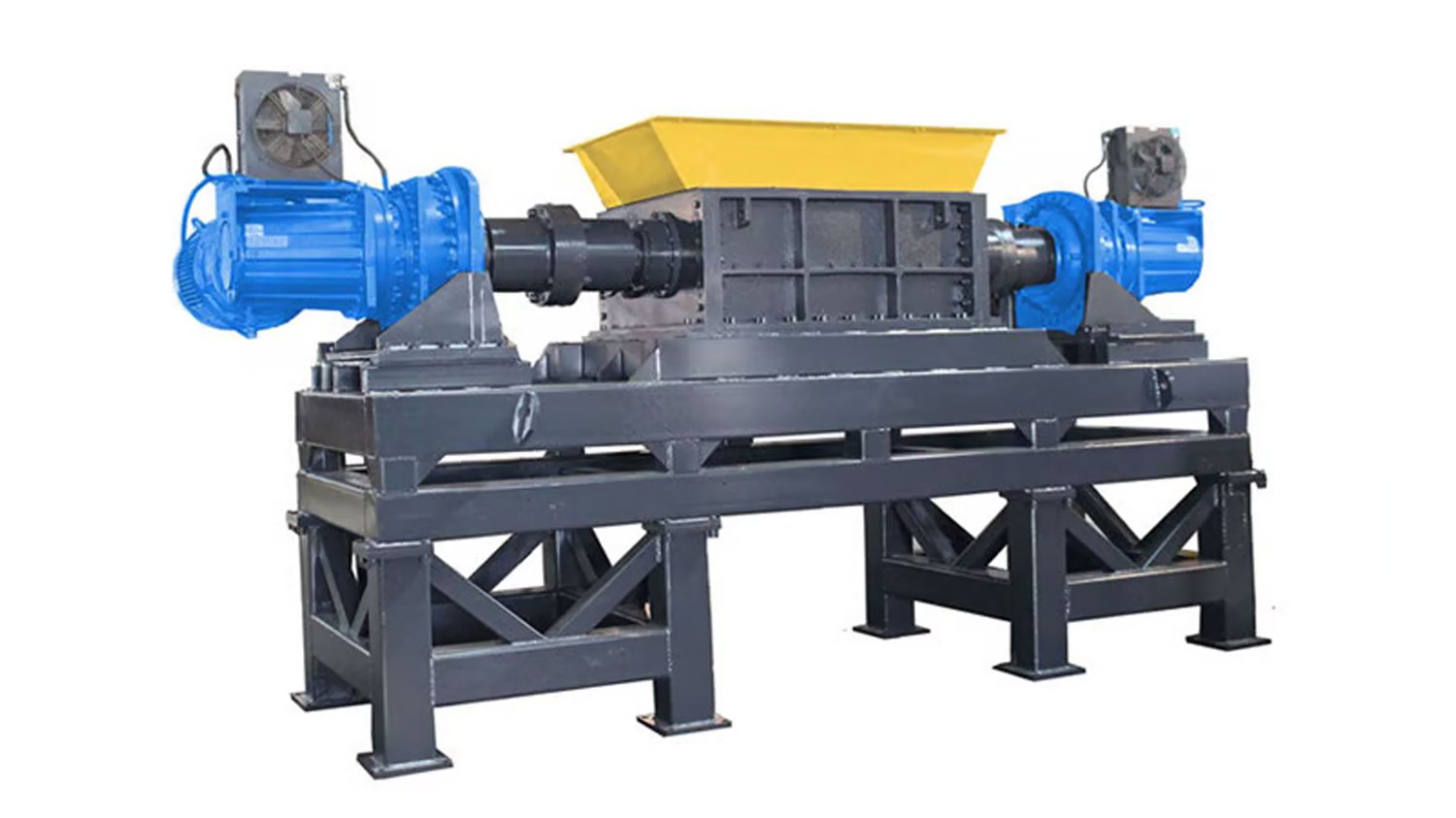

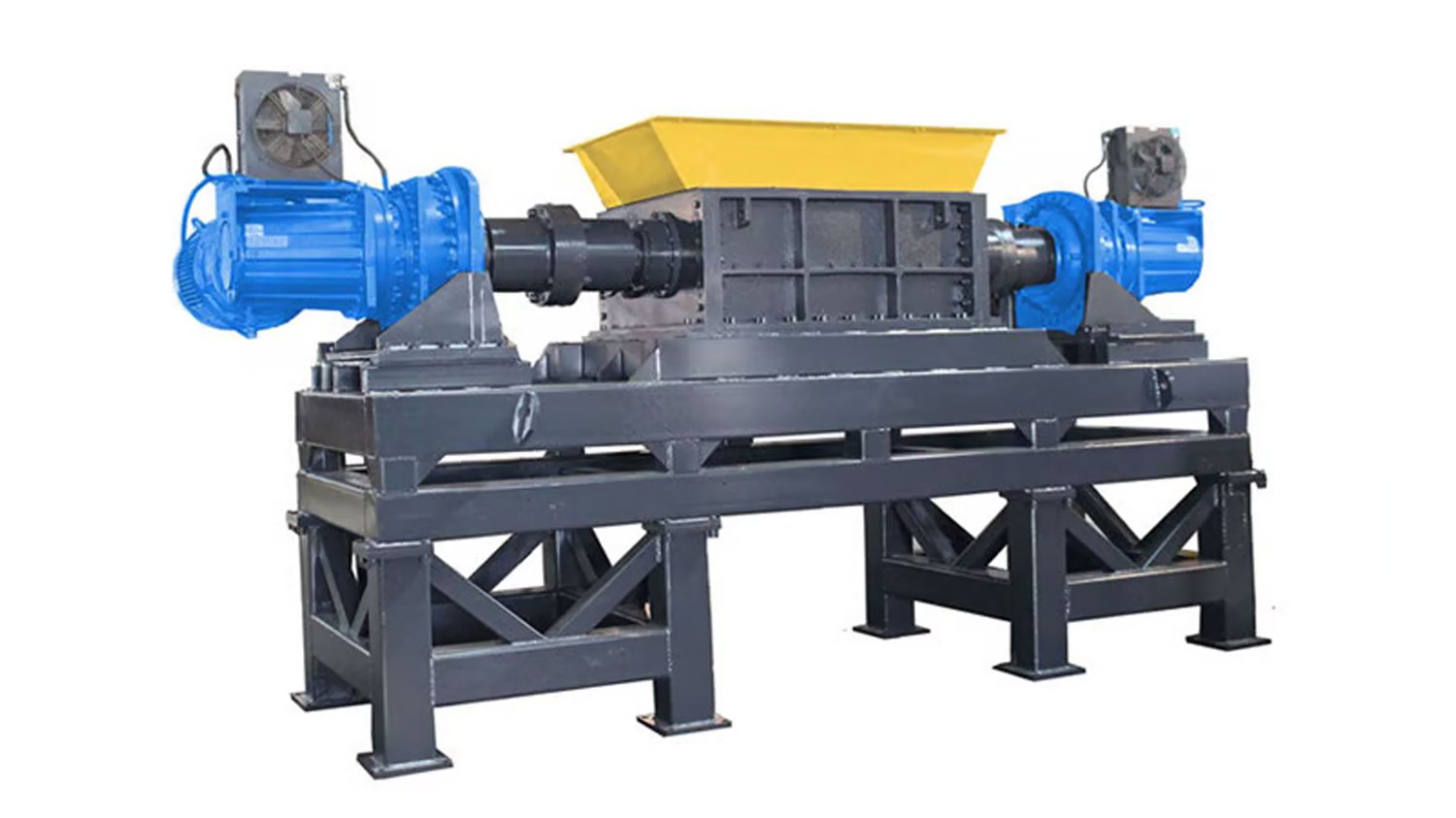

Shredding for Efficient Material Reduction

Shredding is a versatile size reduction technique that is often used for recycling applications. This process involves tearing materials into small pieces using sharp blades or cutters. Shredders are commonly used to process waste materials, plastics, and tires, transforming them into reusable raw materials.

Cutting for Precision Size Reduction

Cutting is a precise method of material size reduction that is commonly used in industries such as metal fabrication and woodworking. This process involves using sharp tools or machines to slice materials into specific shapes or sizes. Cutting is essential for creating precise components and products with tight tolerances.

Benefits of Material Size Reduction

There are numerous benefits to incorporating material size reduction into production processes. These include increased production efficiency, reduced energy consumption, improved material handling, and enhanced product quality. By optimizing size reduction techniques, companies can streamline their operations and stay competitive in the market.

Challenges in Material Size Reduction

Despite its many advantages, material size reduction can present challenges for companies, such as equipment maintenance, energy costs, and material waste. It's essential for businesses to carefully assess their size reduction needs and implement proper solutions to overcome these challenges effectively.

Future Trends in Material Size Reduction

The field of material size reduction is constantly evolving, with new technologies and innovations emerging to improve efficiency and sustainability. Future trends in size reduction may include the use of advanced automation, predictive maintenance, and smart sensors to optimize processes and reduce downtime.

Conclusion

In conclusion, material size reduction is a critical process that impacts various industries and plays a significant role in enhancing productivity and product quality. By understanding the different methods, benefits, and challenges associated with size reduction, companies can make informed decisions to maximize efficiency and stay ahead in a competitive market.

Quote Inquiry

contact us