Table of Contents

As the global demand for sustainable waste management solutions continues to rise, industries are under pressure to find eco-friendly, cost-effective, and efficient ways to treat organic waste. One technology leading this transformation is the environmental dehydration screw press — a powerful tool designed to reduce waste volume, extract valuable resources, and optimize downstream treatment processes.

In this article, we’ll explore how this equipment is revolutionizing waste handling in sectors such as agriculture, food processing, municipal waste, and wastewater treatment.

What Is an Environmental Dehydration Screw Press?

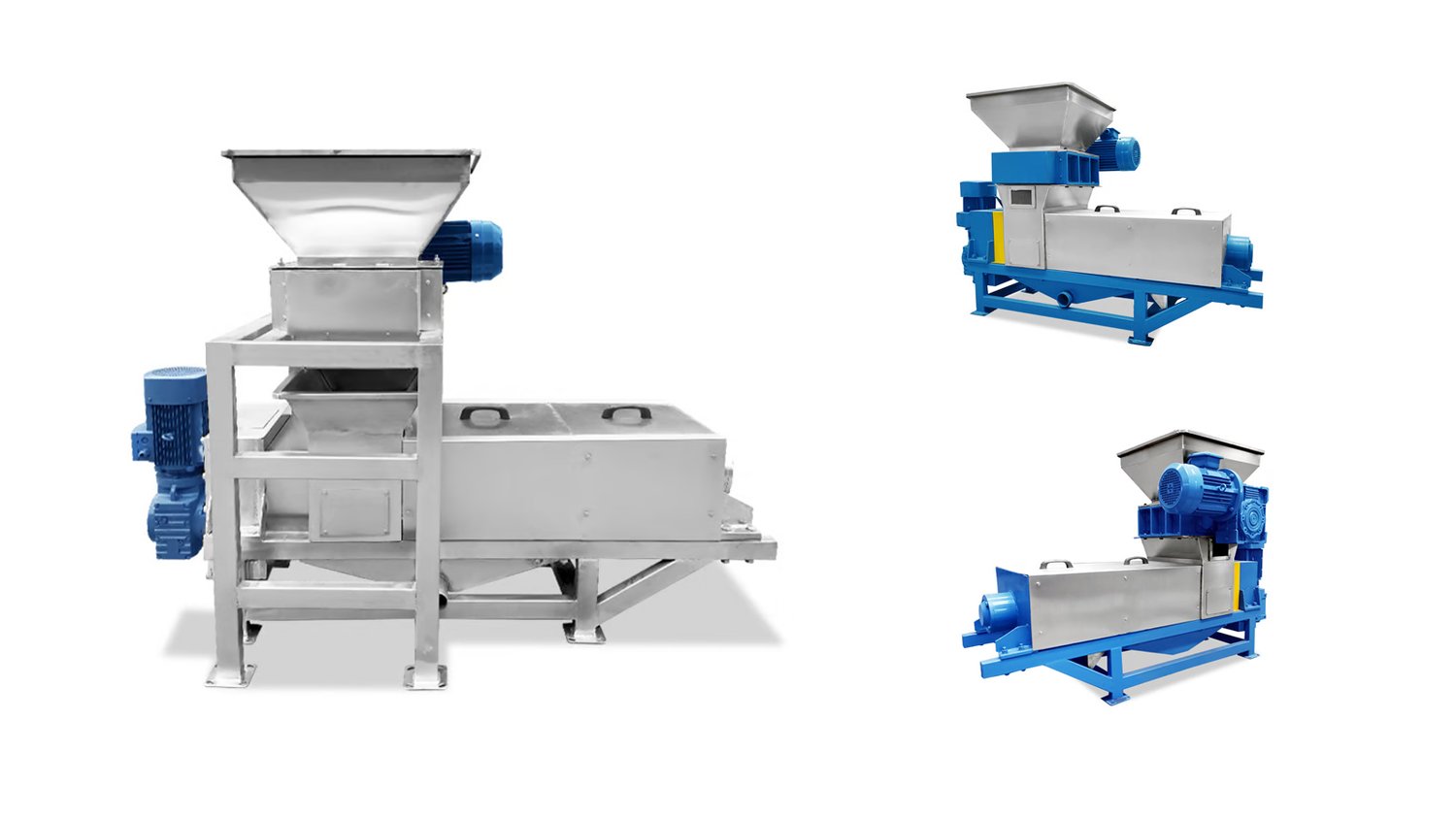

A screw press dehydrator is a mechanical device that separates liquids from solids in waste materials through continuous compression. The equipment features a rotating screw shaft inside a cylindrical screen or perforated drum. As material is fed into the system, pressure is applied, squeezing out the liquid and compacting the solid residue.

Compared with traditional dewatering methods, screw press systems offer:

-

Lower energy consumption

-

High throughput with minimal supervision

-

Compact design and minimal maintenance

-

Compatibility with a wide range of waste materials

Key Applications Across Industries

🏭 Food and Beverage Processing

In juice production, brewery operations, and food packaging, large volumes of organic sludge or peels are produced. Screw presses can effectively dehydrate this organic waste, making it easier to transport, compost, or reuse as animal feed.

🚜 Agricultural Waste Management

Livestock farms generate tons of manure and slurry. With screw press equipment, farms can efficiently separate solids from liquids, reducing odor, simplifying nutrient recovery, and preparing solids for composting or biogas production.

💧 Municipal and Industrial Wastewater Treatment

In sludge dewatering processes, screw presses offer a clean, closed-system solution with low noise and minimal odor. They are ideal for urban sewage plants, industrial effluent stations, and decentralized water treatment systems.

🌿 Biomass and Renewable Energy

In biofuel production and organic digesters, maintaining ideal moisture levels in feedstock is critical. Screw presses help regulate feedstock quality by reducing water content and improving combustion or fermentation efficiency.

Environmental and Economic Benefits

✅ Reduced Waste Volume

Significantly reduces the volume of wet waste, lowering transportation and landfill costs.

✅ Resource Recovery

Separated liquid can be treated or reused, and dry solids can be composted or repurposed.

✅ Energy Efficiency

Low power consumption compared to thermal drying or centrifuges.

✅ Minimal Operating Costs

Designed for continuous operation with minimal labor and low maintenance.

✅ Improved Hygiene and Odor Control

Closed system design minimizes air and water pollution, supporting safer waste handling.

Smart Features of Modern Screw Press Dehydrators

-

Automatic cleaning system

-

Variable speed control for adjusting pressure and output

-

304/316 stainless steel construction for corrosion resistance

-

Compact skid-mounted designs for easy installation

-

PLC control + remote monitoring for smart operation

Case Study: Dairy Farm Sludge Management

A 500-cow dairy farm in Germany adopted an environmental screw press system to treat cattle manure. After implementation:

-

Solids content increased from 5% to 28%

-

Monthly waste transport volume reduced by 60%

-

Separated liquid reused for field irrigation

-

Solid waste used as bedding material and composted

The result: lower operating costs, improved resource utilization, and compliance with EU waste regulations.

Conclusion: A Smarter Future for Waste Management

The environmental dehydration screw press is more than just a piece of equipment — it’s a sustainable solution for modern waste challenges. By minimizing waste volume, recovering resources, and enabling cleaner operations, it aligns perfectly with the goals of circular economy and green production.

Whether you're managing sludge in a food factory or treating manure on a large-scale farm, this technology empowers industries to turn waste into value — efficiently, sustainably, and profitably.