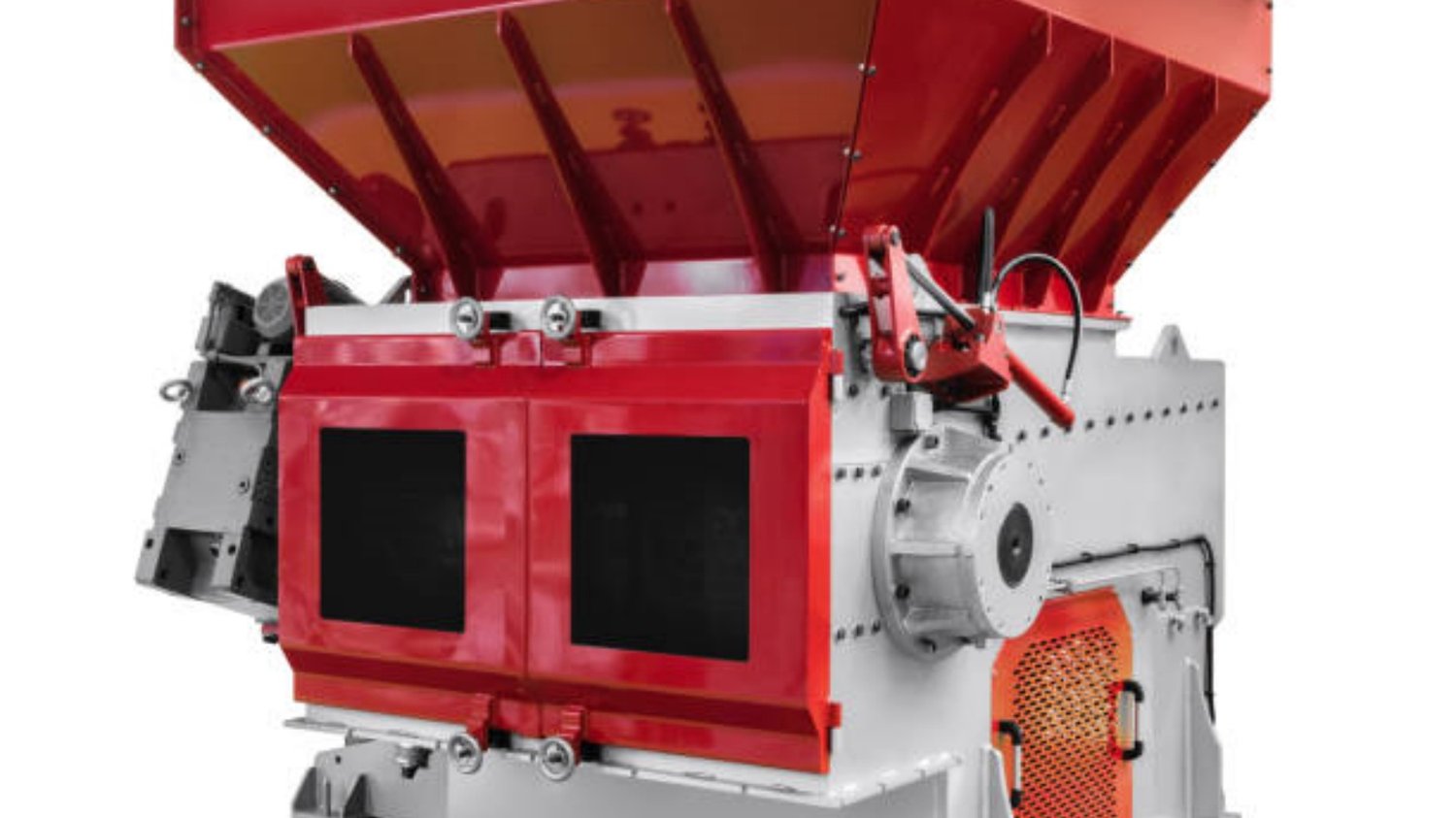

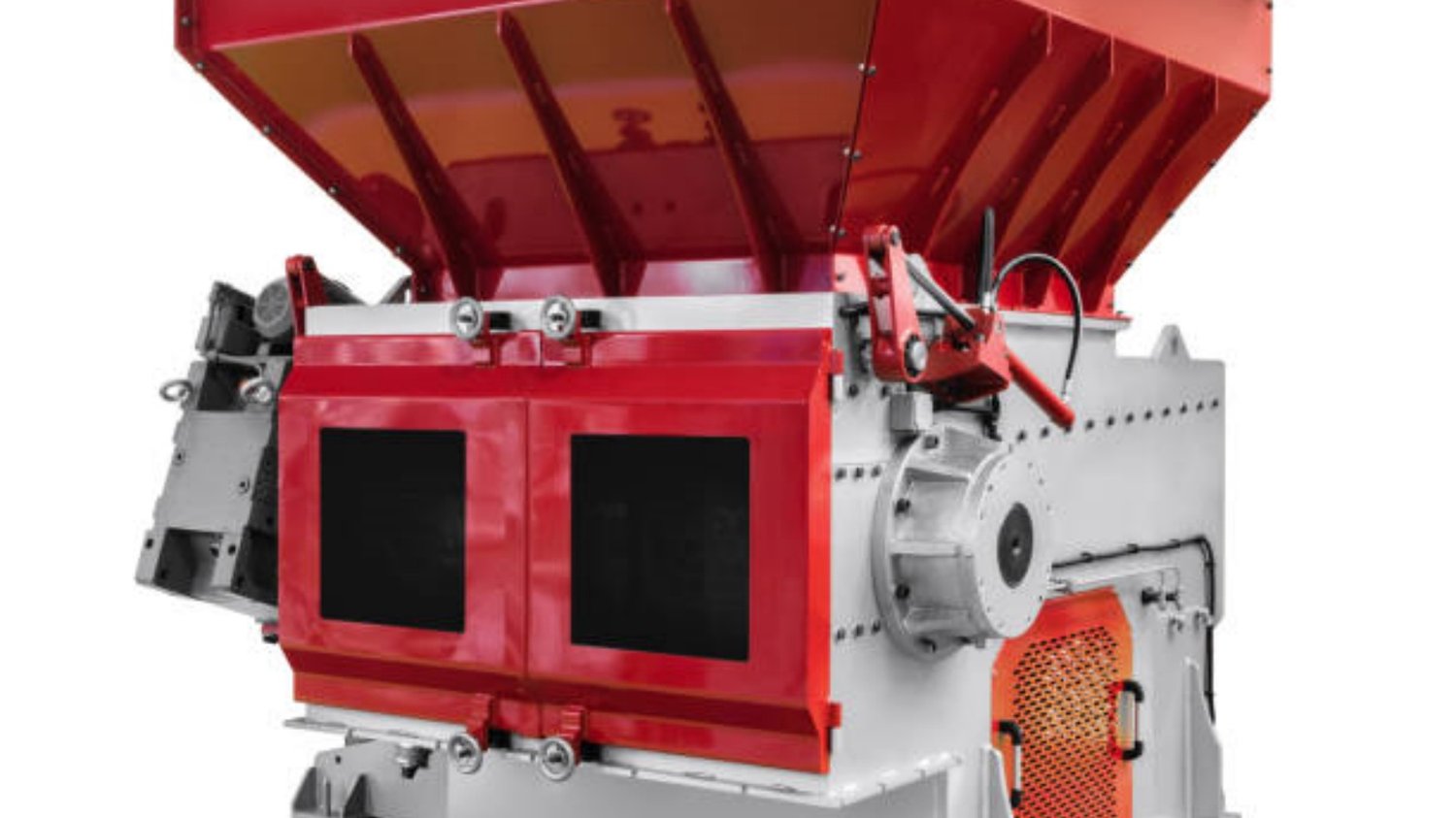

Understanding the Importance of Regular Shaft Crusher Maintenance

Maintaining a shaft crusher is critical for maximizing its efficiency and longevity. Regular maintenance prevents unexpected breakdowns and costly repairs. By adhering to a consistent maintenance schedule, operators can ensure that the shaft crusher operates at peak performance, reducing downtime and enhancing productivity.

Daily Inspection Procedures for Shaft Crusher Components

Daily inspections are a cornerstone of effective shaft crusher maintenance. Operators should check for wear and tear on critical parts such as the shaft, jaws, and bearings. Identifying early signs of damage, such as unusual vibrations or noises, allows prompt corrective action and prevents serious failures.

Lubrication Best Practices for Shaft Crusher Longevity

Proper lubrication of moving parts is essential to shaft crusher maintenance. Using the correct type and amount of lubricant minimizes friction and wear on the shaft and associated components. A well-lubricated crusher runs smoothly, decreases energy consumption, and extends the machine’s operational life.

Cleaning Protocols to Prevent Material Build-Up

Material build-up can cause inefficiencies and damage to a shaft crusher. Implementing a routine cleaning schedule removes accumulated debris from the crushing chamber and shaft area. Effective cleaning reduces the risk of blockages, overheating, and uneven wear during operation.

Monitoring and Replacing Wear Parts Timely

Wear parts such as crusher jaws and wear plates are subject to constant abrasion and need regular monitoring.

Shaft Crusher Maintenance Tips emphasize tracking wear rates and replacing these parts before they reach critical levels. This approach maintains crushing efficiency and prevents damage to other components.

Checking Shaft Alignment and Balancing

Misalignment and imbalance in the shaft can lead to excessive vibration, noise, and accelerated wear. Regular alignment checks ensure the shaft operates smoothly within design tolerances. Correct balancing improves machine stability and contributes to consistent crushing performance.

Implementing Vibration and Temperature Monitoring Systems

Advanced shaft crusher maintenance tips recommend incorporating vibration and temperature sensors. These systems detect anomalous operating conditions early, such as bearing failure or shaft misalignment. Monitoring these parameters aids predictive maintenance, reducing unplanned stoppages.

Ensuring Proper Tension in Drive Belts and Chains

The drive mechanism of a shaft crusher relies on precise belt or chain tension to transmit power efficiently. Loose or overly tight belts can cause slippage or premature failure. Routine inspection and adjustment of these drive components are vital components of shaft crusher maintenance tips for optimal operation.

Training Operators on Correct Usage and Maintenance

Operator knowledge directly impacts the effectiveness of shaft crusher maintenance. Training programs should cover correct operation, troubleshooting, and routine maintenance tasks. Well-trained personnel can identify problems early and perform essential upkeep, preserving machine integrity.

Documenting Maintenance Activities and Scheduling Preventive Actions

Maintaining detailed logs of all maintenance activities provides valuable insights into the shaft crusher’s condition over time. Scheduled preventive maintenance, based on these records, helps plan part replacements and service tasks, reducing unexpected failures and extending equipment life.

Quote Inquiry

contact us