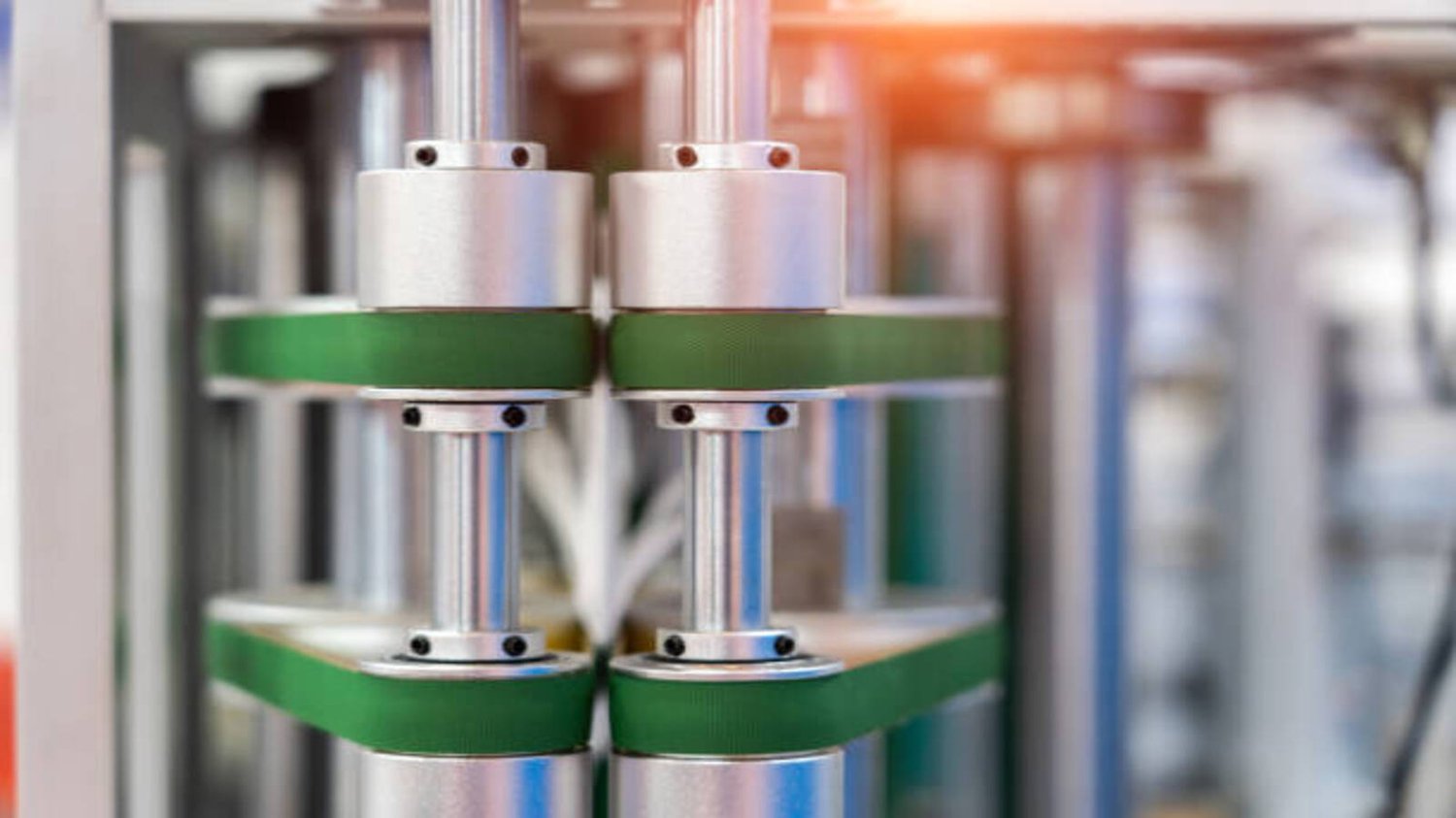

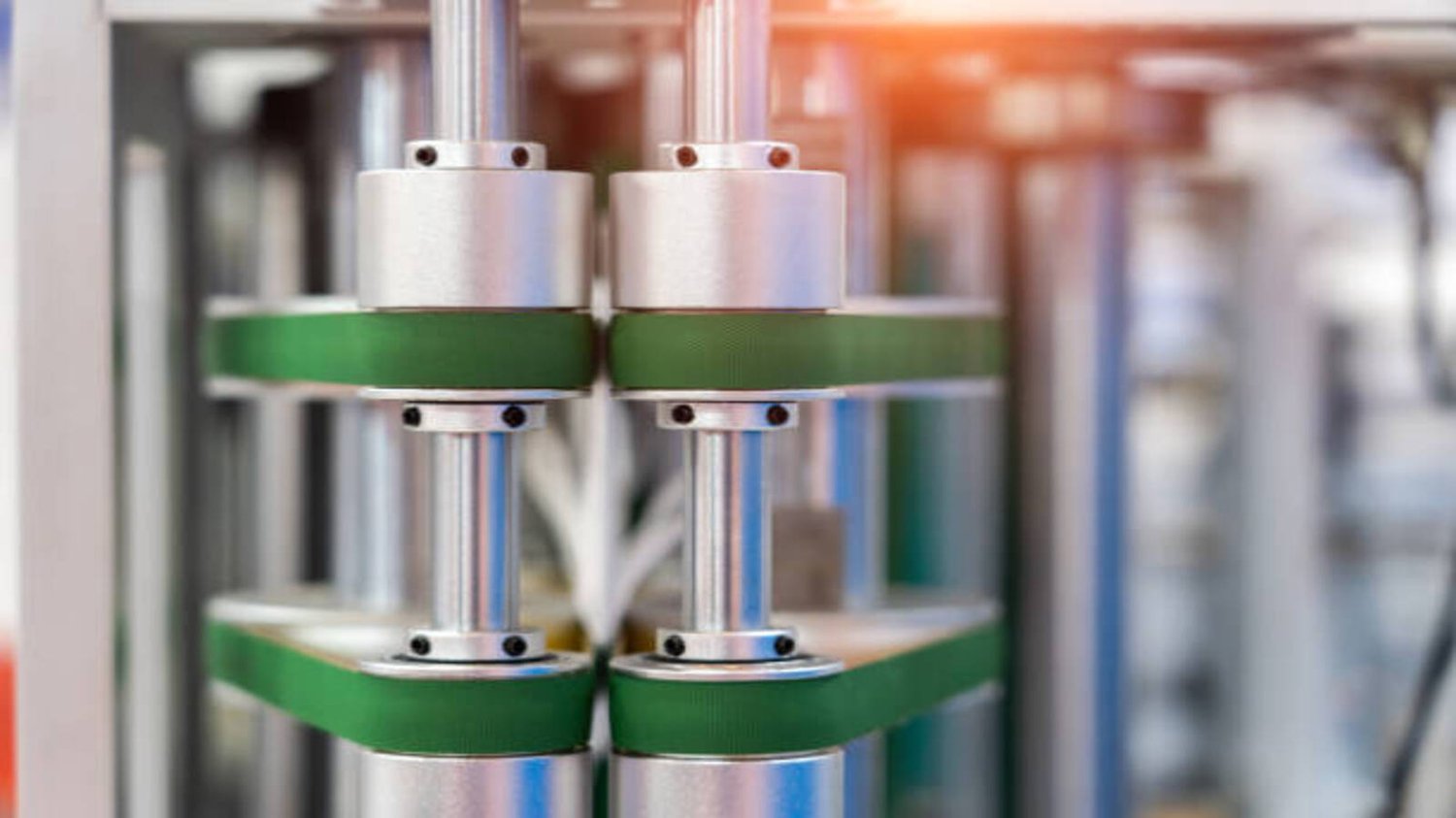

What Are Custom Screw Press Machines?

Custom screw press machines are specialized equipment used in metal forming processes. These machines use a screw mechanism to apply pressure and force in order to shape and mold metal materials. They are highly versatile and can be customized to meet specific production requirements.

Benefits of Using Custom Screw Press Machines

There are numerous benefits to using

custom screw press machines for metal forming. These machines offer precision and accuracy in shaping metals, resulting in high-quality finished products. They are also efficient and can increase production speed, leading to cost savings and improved overall productivity.

Types of Custom Screw Press Machines

There are several types of custom screw press machines available for metal forming applications. Some common variations include mechanical screw presses, hydraulic screw presses, and pneumatic screw presses. Each type has its own unique features and advantages, making it suitable for different production needs.

Customization Options for Screw Press Machines

One of the key advantages of custom screw press machines is the ability to customize them according to specific requirements. Manufacturers can tailor these machines to accommodate various metal materials, sizes, and shapes. Customization options also include control systems, automation features, and safety mechanisms.

Applications of Custom Screw Press Machines

Custom screw press machines are used in a wide range of metal forming applications across various industries. They are commonly employed in processes such as forging, extrusion, stamping, and deep drawing. These machines are essential for producing a diverse array of metal products, from automotive parts to aerospace components.

Factors to Consider When Choosing a Custom Screw Press Machine

When selecting a custom screw press machine for metal forming, there are several factors to consider. These include the type of metal material being used, the desired production output, the level of precision required, and the available budget. It is important to work with a reputable manufacturer who can provide expert guidance on selecting the right machine for your needs.

Advancements in Custom Screw Press Machine Technology

The field of custom screw press machines is constantly evolving with advancements in technology. Manufacturers are incorporating new features such as digital controls, predictive maintenance systems, and energy-efficient designs. These innovations improve machine performance, reliability, and user-friendliness.

Custom Screw Press Machine Maintenance and Care

Proper maintenance and care are essential for maximizing the lifespan and efficiency of custom screw press machines. Regular inspections, lubrication, and cleaning are necessary to prevent wear and tear. Manufacturers typically provide maintenance guidelines and support to ensure optimal machine performance.

Cost Considerations for Custom Screw Press Machines

Investing in custom screw press machines for metal forming is a significant decision that requires careful consideration of costs. The price of these machines can vary depending on factors such as size, capacity, features, and customization options. It is important to weigh the initial investment against the long-term benefits and ROI of the machine.

Choosing a Reliable Manufacturer for Custom Screw Press Machines

When purchasing custom screw press machines, it is crucial to select a reliable and reputable manufacturer. Look for a company with a proven track record of delivering high-quality machines, excellent customer service, and ongoing support. Working with a trusted manufacturer ensures a smooth and successful integration of custom screw press machines into your metal forming processes.

Quote Inquiry

Contact us!