A mini screw conveyor is a small, versatile conveying system that is often used in industrial settings to move materials from one place to another. These screw conveyors are compact in size but can handle a wide range of materials, making them ideal for a variety of applications.

How Does a Mini Screw Conveyor Work?

Mini screw conveyors operate by rotating a helical screw blade inside a tube, which effectively moves materials along the conveyor. The rotation of the screw blade creates a force that pushes the materials forward, allowing for efficient and controlled movement of the materials.

Benefits of Using Mini Screw Conveyors

Mini screw conveyors offer several advantages, including their small size, versatility, and ease of use. They are also cost-effective, reliable, and low-maintenance, making them a popular choice for many industries.

Applications of Mini Screw Conveyors

Mini screw conveyors are commonly used in industries such as food processing, pharmaceuticals, agriculture, and manufacturing. They are ideal for conveying materials such as powders, granules, and small particles in a controlled manner.

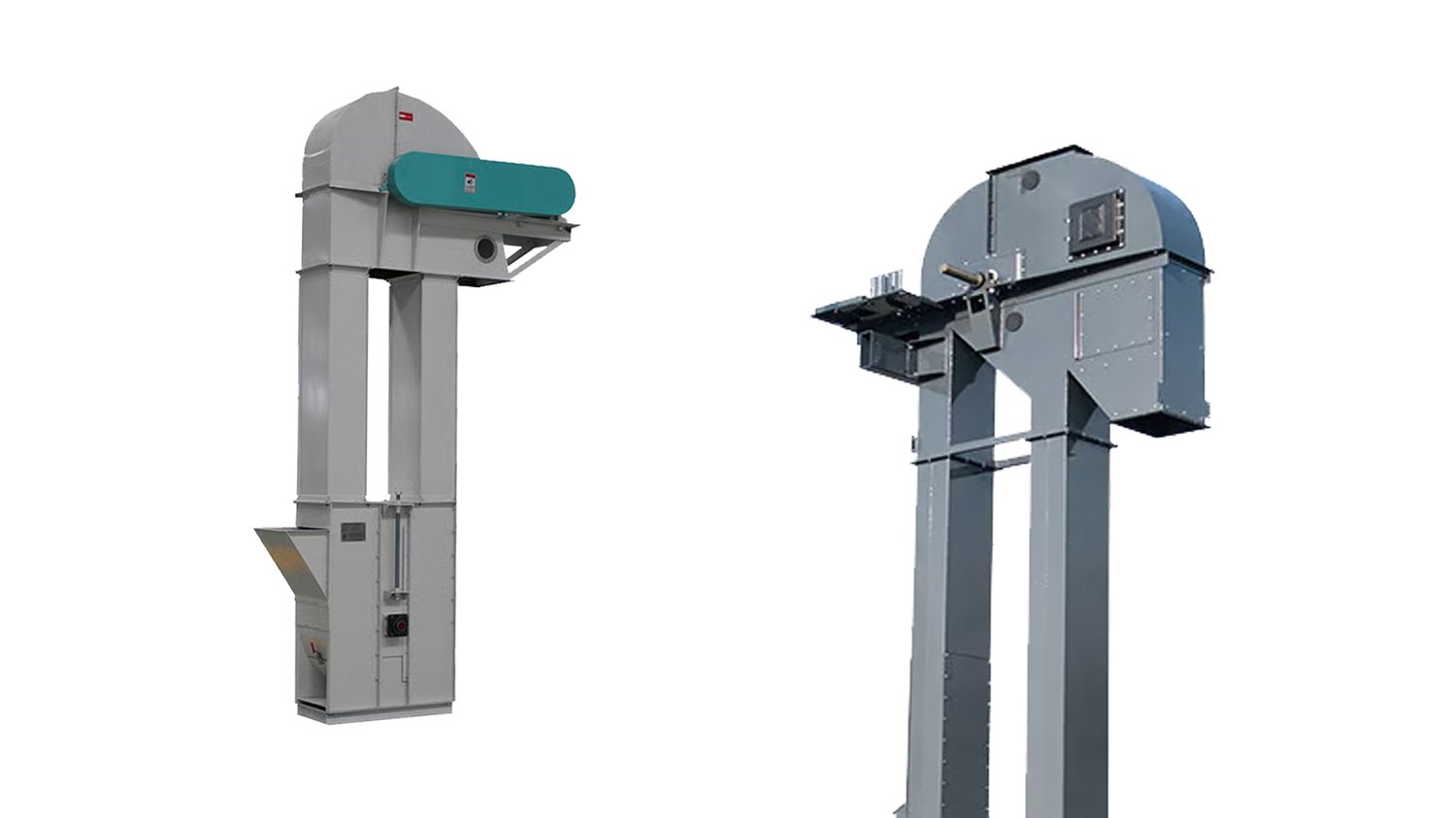

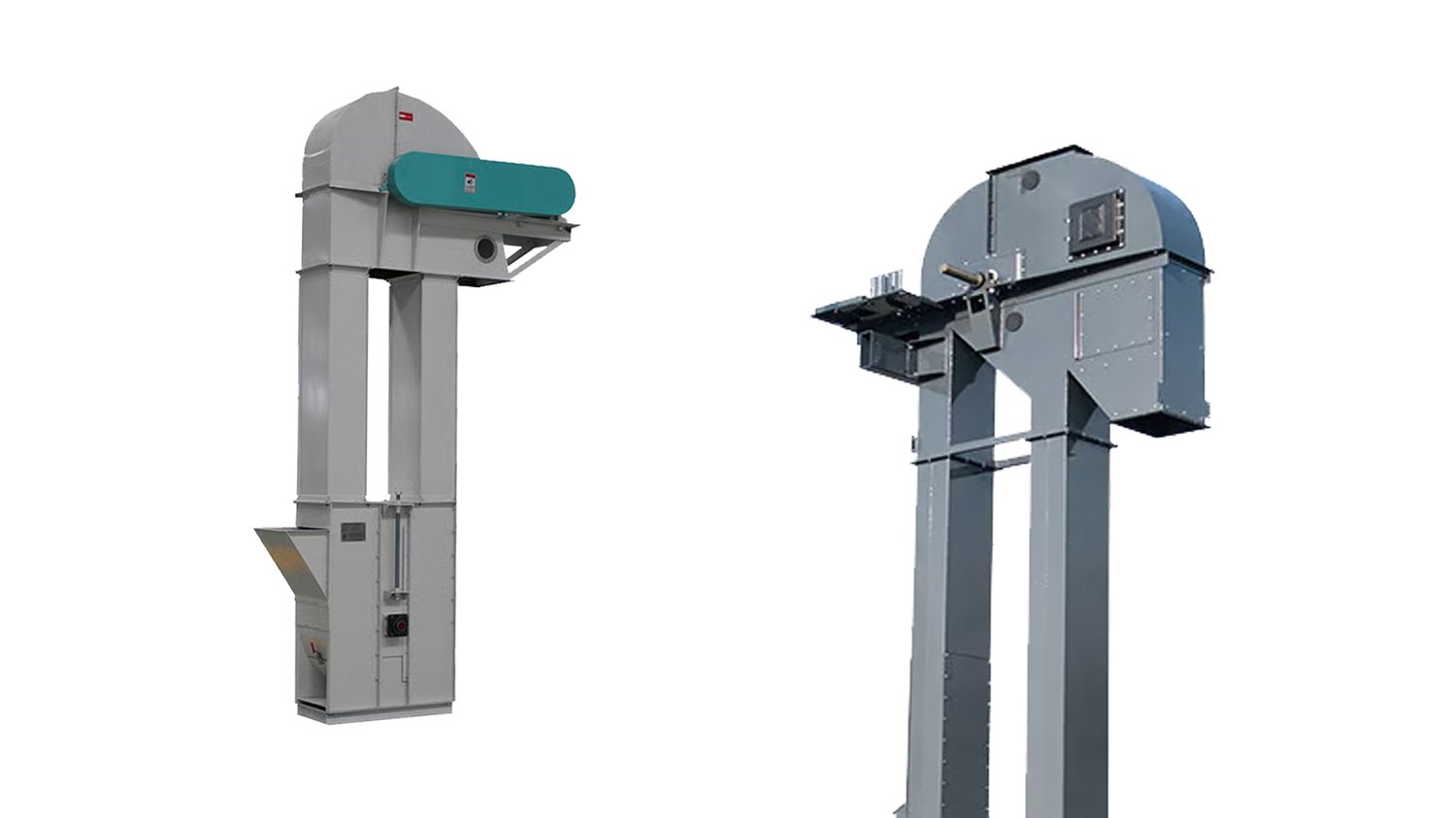

Types of Mini Screw Conveyors

There are various types of mini screw conveyors available, including horizontal, vertical, inclined, and shaftless conveyors. Each type is designed for specific applications and can be customized to meet the unique needs of different industries.

Factors to Consider When Choosing a Mini Screw Conveyor

When selecting a mini screw conveyor, it is important to consider factors such as the type of material being conveyed, the required capacity, the conveyor's configuration, and any specific requirements for the application. By carefully considering these factors, you can ensure that you choose the right conveyor for your needs.

Installation and Maintenance of Mini Screw Conveyors

Proper installation and maintenance are essential for ensuring the efficient operation of mini screw conveyors. Regular inspections, lubrication, and cleaning are necessary to prevent issues such as clogging, wear, and breakdowns. Following the manufacturer's guidelines is crucial for maintaining the conveyor's performance.

Future Trends in Mini Screw Conveyor Technology

As technology advances, mini screw conveyors are expected to become more advanced and efficient. Innovations such as smart sensors, automation, and energy-saving features are likely to be incorporated into future conveyor designs, enhancing their performance and reliability.

Environmental Impact of Mini Screw Conveyors

Mini screw conveyors are known for their energy efficiency and low environmental impact. By using these conveyors, industries can reduce energy consumption, minimize waste, and lower their carbon footprint, contributing to a more sustainable future.

Conclusion

In conclusion, mini screw conveyors are valuable tools for moving materials efficiently in various industrial applications. With their compact size, versatility, and cost-effectiveness, these conveyors offer a reliable and effective solution for conveying a wide range of materials.

Quote Inquiry

contact us