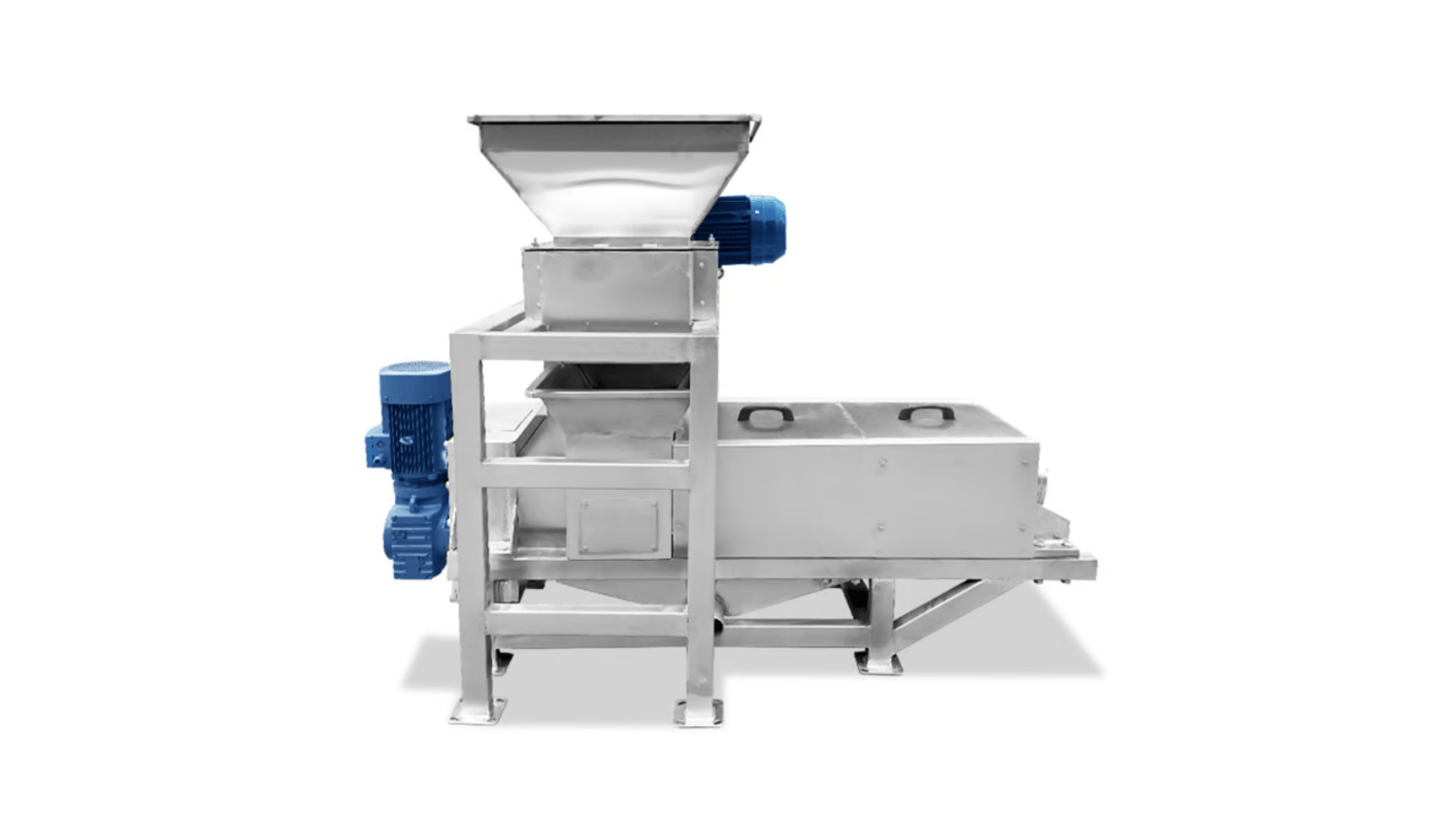

Shredder squeezer machines combine two essential industrial processes—shredding and squeezing—into a single versatile unit. These machines are designed for efficiently breaking down various materials while simultaneously extracting moisture or other liquids through compression. Widely used in recycling, waste management, and manufacturing industries, shredder squeezer machines optimize material handling by minimizing volume and preparing substances for further processing or disposal.

2. Core Components and Working Mechanism

At the heart of the shredder squeezer machine lies an integrated mechanism comprising high-torque shredding blades and hydraulic or mechanical squeezing units. The shredding component reduces bulk by cutting materials into uniform fragments, while the squeezer applies pressure, extracting fluids such as oils, water, or chemical residues. This dual operation not only facilitates efficient material downsizing but also enhances drying, reduces weight, and improves transport efficiency.

3. Industrial Applications of Shredder Squeezer Machines

Various industries benefit from shredder squeezer machines, including food processing, plastic recycling, paper and cardboard waste management, and metal recycling. In food industries, for example, these machines help shred and press fruit or vegetable waste to extract juice while reducing solid waste volume. In recycling plants, they shred plastics or rubber and squeeze out embedded liquids, making recycling operations cleaner and more efficient.

4. Advantages of Integrating Shredding and Squeezing

The combined functionality within shredder squeezer machines streamlines production processes, reduces equipment footprint, and lowers operational costs. By integrating shredding and squeezing, companies save time on handling materials separately, reduce energy consumption, and improve throughput. Additionally, the consistent output of shredded and dried material aids in meeting regulatory standards for waste management and recycling.

5. Material Compatibility and Versatility

Shredder squeezer machines are engineered to handle a broad spectrum of materials, including organic waste, plastics, paper, metal scraps, and textiles. Their adjustable shredding knives and squeezing pressure settings can be customized depending on the specific properties of materials, such as toughness, moisture content, and thickness. This versatility makes shredder squeezer machines indispensable tools across diverse sectors.

6. Environmental Impact and Sustainability Benefits

Utilizing shredder squeezer machines contributes significantly to sustainable waste management practices. By reducing waste volume and extracting liquids that can be treated separately, these machines lower landfill dependency and minimize environmental contamination risks. Furthermore, by facilitating recycling and reuse processes, shredder squeezer machines help industries reduce their carbon footprint and support circular economy initiatives.

7. Technological Innovations in Shredder Squeezer Machines

Recent advancements in shredder squeezer machine technology include automation, enhanced cutting blade materials, and sophisticated control systems. Modern machines incorporate sensors and PLC (Programmable Logic Controller) interfaces for real-time monitoring, ensuring optimal shredding and squeezing performance. Innovations also focus on energy efficiency, noise reduction, and improved safety features, making these machines more user-friendly and cost-effective.

8. Maintenance and Operational Best Practices

Proper upkeep is crucial for maintaining the efficiency and longevity of shredder squeezer machines. Regular blade inspection and sharpening prevent downtime caused by blunt cutting edges. Lubrication of moving parts, timely replacement of hydraulic fluids, and periodic system calibration ensure consistent squeezing pressure. Adhering to manufacturer-recommended maintenance schedules not only maximizes output quality but also reduces the risk of operational failures.

9. Cost Considerations and ROI Analysis

Investing in a shredder squeezer machine requires a careful cost-benefit analysis that considers machine price, installation, maintenance, and expected productivity gains. While the initial investment may be significant, the reduction in waste handling costs, improved material recycling value, and lower labor expenses usually deliver a favorable return on investment (ROI). Evaluating specific use cases and operational needs helps businesses select the most cost-efficient shredder squeezer machine model.

10. Future Outlook and Market Trends

The market for shredder squeezer machines is projected to grow steadily due to increasing regulatory pressures on waste reduction and growing demand for sustainable manufacturing practices. Emerging trends include the development of compact, modular shredder squeezer units tailored for small and medium enterprises. Additionally, integration with IoT (Internet of Things) technology for data-driven maintenance and optimization continues to transform the capabilities of shredder squeezer machines, positioning them as pivotal assets in modern production environments.

Quote Inquiry

contact us