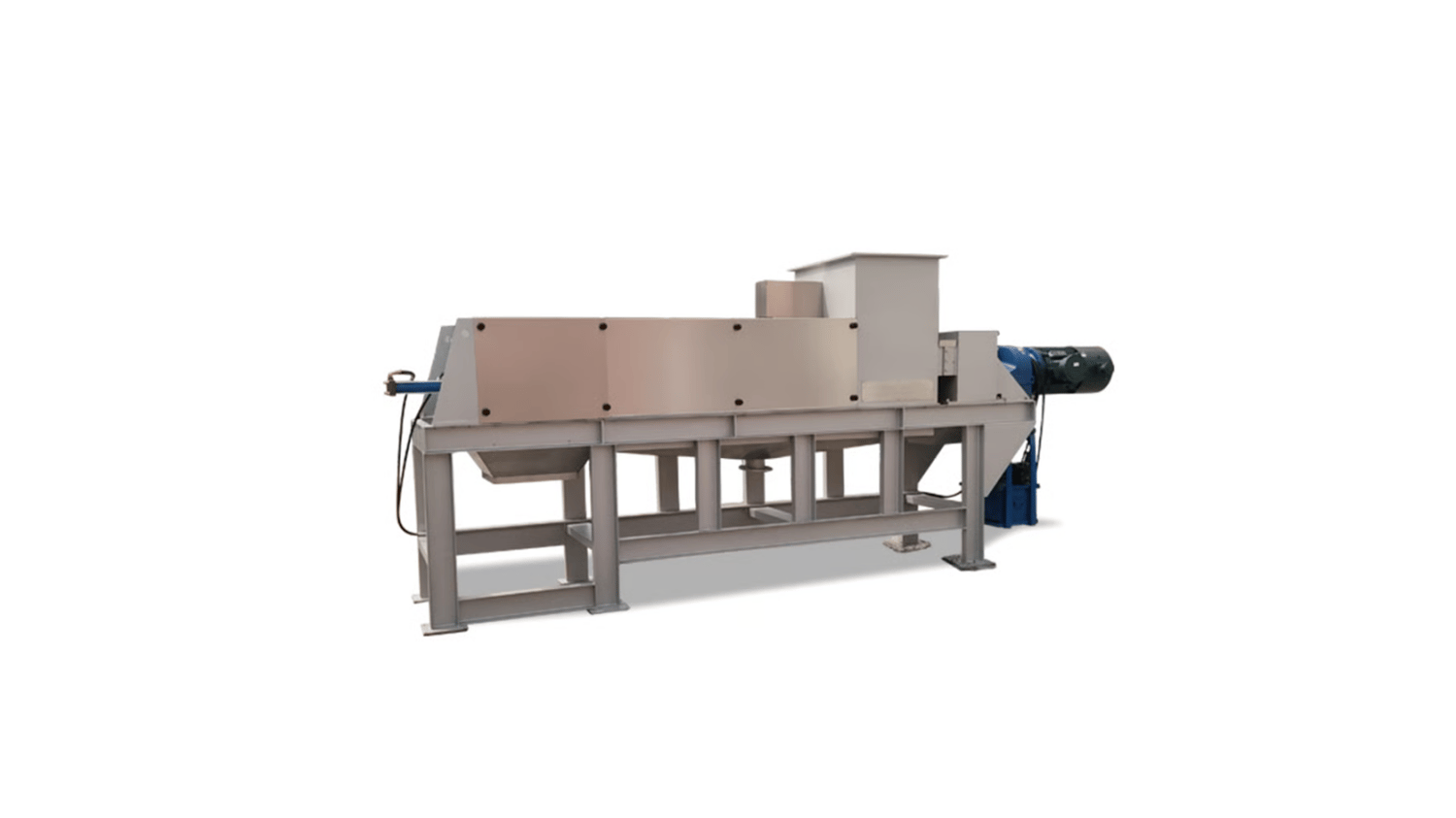

Understanding the Fundamentals of Variable diameter screw press

A variable diameter screw press is an advanced mechanical device designed to compress and separate liquids from solids using an adjustable screw mechanism. Unlike fixed diameter screws, this technology allows the screw’s diameter to vary along its length, optimizing throughput and pressure according to the material being processed. This adaptability enables better control over the pressing process, making it indispensable in industries that require precise dewatering or material compaction.

Key Design Features Driving Performance

The variable diameter screw press integrates a changing screw diameter, typically expanding or contracting from the feed end to the discharge end. This gradual diameter variation enhances the pressure applied on the material progressively, ensuring maximum extraction efficiency. Additionally, modern designs incorporate corrosion-resistant materials and modular components, improving durability and maintaining consistent operation under diverse industrial conditions.

Applications Across Multiple Industries

Variable diameter screw presses serve essential roles in sectors such as agriculture, waste management, chemical processing, and food production. For instance, in oilseed processing, they are used for oil extraction by efficiently separating oil from seed cake. Similarly, in wastewater treatment, they dewater sludge efficiently, reducing disposal costs and environmental impact. This versatility underscores the machine's importance in modern industrial processes.

Enhanced Throughput and Energy Efficiency

One of the standout advantages of a variable diameter screw press is its ability to handle varying material loads with optimized energy consumption. By adjusting the screw diameter, the press can maintain consistent pressure and flow rates, reducing mechanical stress and energy waste. This leads to lower operational costs and improved sustainability — critical factors in today’s energy-conscious industries.

Customization and Scalability

Manufacturers often offer variable diameter screw presses tailored to specific material characteristics and production scale. Customizations may include screw length, pitch, diameter variation rate, and supplementary features like integrated screening or heating elements. Moreover, the modular design facilitates scalability, allowing operators to upgrade capacity without complete system replacement, thereby reducing capital expenditures.

Operating Principles and Process Control

In operation, material is fed into the press’s screw chamber, where the varying diameter gradually compresses it as it moves toward the outlet. This compression forces fluids out through perforated screens while solids are compacted and expelled. Process controls incorporating pressure sensors and adjustable screw speed further enhance performance, enabling operators to fine-tune extraction based on real-time data.

Maintenance and Longevity Considerations

Due to the mechanical complexity and continuous operation, maintenance of variable diameter screw presses is critical. Routine inspection of the screw flight wear, bearings, and sealing components ensures prolonged machine life. The use of replaceable screw sections and wear-resistant coatings can significantly reduce downtime and maintenance costs, contributing to long-term operational reliability.

Comparing Fixed Diameter vs. Variable Diameter Screw Presses

While fixed diameter screw presses maintain a constant screw profile, variable diameter models offer dynamic pressure adjustment, resulting in higher extraction efficiency and versatility. Fixed diameter presses are generally simpler and less costly but are limited in handling variable input material consistency or moisture content. Therefore, industries requiring adaptable processing benefit more from variable diameter designs.

Environmental Impact and Sustainability Benefits

Variable diameter screw presses contribute to environmental sustainability by improving dewatering effectiveness and minimizing waste volumes. This reduces landfill dependency and lowers the energy consumption associated with post-processing disposal. Additionally, efficient liquid separation can enable recycling and reuse, further mitigating environmental footprints in waste-intensive industries.

Future Trends and Technological Innovations

Emerging trends in variable diameter screw press technology focus on automation, integration with IoT systems, and advanced materials to boost performance and predictive maintenance capabilities. Developments in sensor technology allow for real-time process optimization, while new alloys and coatings extend operational durability. These innovations are poised to enhance the role of variable diameter screw presses in next-generation industrial applications.

Quote Inquiry

contact us