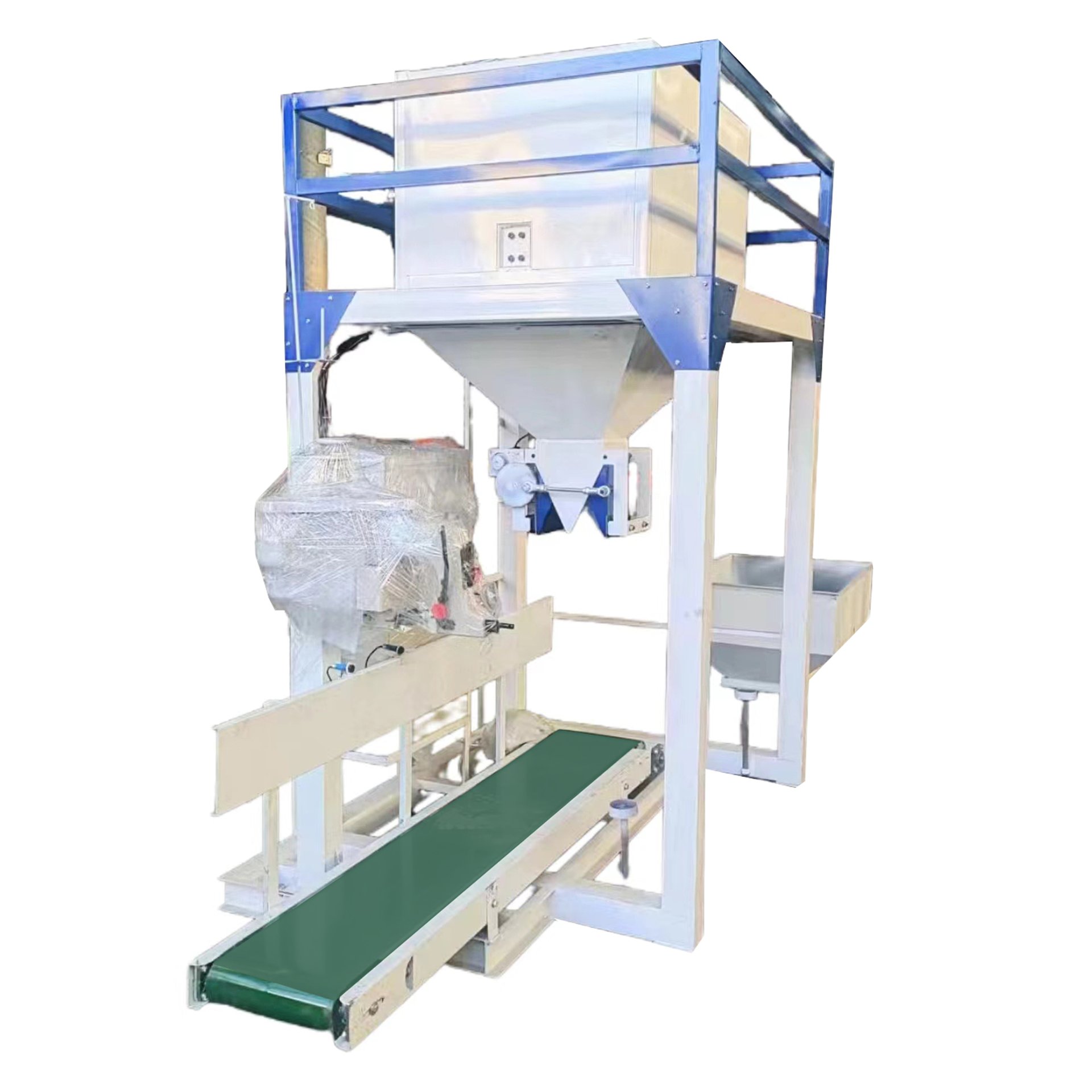

Bagging Machine

Henan Tianzhong is a leading brand specializing in the manufacturing of dewatering screw press, solid-liquid separators, vegetable pulping machines, screw conveyors, and trash can lifters, etc.We are an integrated solution provider of dehydration and reduction of waste material in various industries,R&D,production and sales of complete sets of fine filtration equipmenet.Choose our OEM/ODM services for a combination of speed and quality.Tianzhong Machinery,You First Option, Longlife Benefit!

Brief Description

DCS-50 series Semi-Auto Weighing Filling Machine consisting of various series of electronic scales and sewing conveyor.It suits for packing of bulk material of particle and powder with good fluidity.(such as grain,beans,fertilizer,chemical and other industries.)The rated rang of packing weight is 5kg-80kg.The feeding, weighing, and discharging processes of the equipment are all automatically controlled by an intelligent electrical control system.

All our packaging machine accessories use famous brands, such as AirTAC for pneumatic components, WEINVIEW / Delta for HMI (color touch screen panels), Schneider / CHNT for electrical components, Load cells, we install 3 KELI load cells (maximum weight 200kg / pc , IP67) or Mettler Toledo as required. Our bagging machine is designed to operate stably for over years.

Characteristic

It has the characteristics of a reasonable structure,a beautiful appearance,stable operation,energy saving and power saving,easy operation and accurate weighing.It has achieved international advanced standard and meets the European CE standard.

Technical parameter

| Application | Powder or ultra-fine powder material |

| Accuracy | 0.20% |

| Display Resolution | 5g,10g |

| Weight Range | 20-50kg |

| Packing Speed | 300-360bags/hour |

| Dimension | 850*1250*3285(mm)/850*1678*3443(mm) |

| Power | AC220V/380V 50HZ |

| Air source | 0.5-0.7Mpa |

| Temperature Range | -10-40° |

| Relative humidity | ≤90%RH(Non-condensing) |

Usage and Maintenance Tip:

-

When the equipment stops working at the end of each shift or for other reasons, it should be shut downAll the remaining materials in the machine should be emptied,and the power and gas sources should also be turned off.

-

Before each shift, add 10# Lubricating oil to the oil mist lubricator according to regulations and empty the water filter’s sewage.

-

After each shift, all parts of the machine should be cleaned,and compress air should be used to purge them.Do not use water to wash the machine, especially the electronic scale and sensors.

-

When the equipment is not in use for a long time, all parts of the machine should be thoroughly cleaned.The exposed parts of carbon steel should be coated with rust-resistant oil.the active parts should be properly lubricated, and the moving parts should be secured fastened.Additionally,a plastic film should be used to protect the equipment.

-

If a fault occurs in the electrical control system while the equipment is in use,immediate power shutdown is required.Under such circumstances,users must not attempt to repair it themselves,Instead,they should notify our company so that we can arrange for the necessary repairs.